Special Mixing heads

The right mixing head for every special application

Product information

Whether spraying, flooding, fiber reinforcement, or precise dosing: our mixing heads cover a wide range of PUR processes and offer the right technology for every challenge. From high-precision high-pressure mixing heads to flexible low-pressure solutions, all systems stand for excellent mixing quality, reliable process control, and maximum design freedom for your production.

Use cases

Industries

A solution for every application

Our spray mixing heads have been specially developed for the requirements of a wide range of spray technologies – with the aim of offering you maximum flexibility and creative freedom in design. Whether complex geometries, fine surfaces or large-area applications: the technology behind our spray mixing heads ensures uniform, precise distribution of the material, enabling high-quality results in every application.

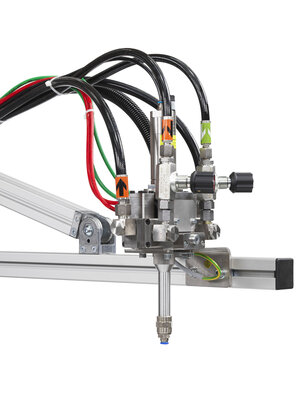

Core features of the spray mixing head

- Armored mixing head for highly filled PUR systems

- Excellent mixing quality even with extreme mixing ratios

- Low overspray, sharp spray boundaries

- Material savings through optimal material application

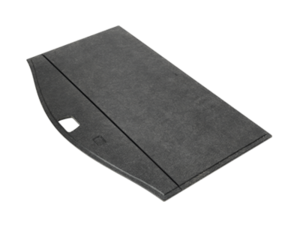

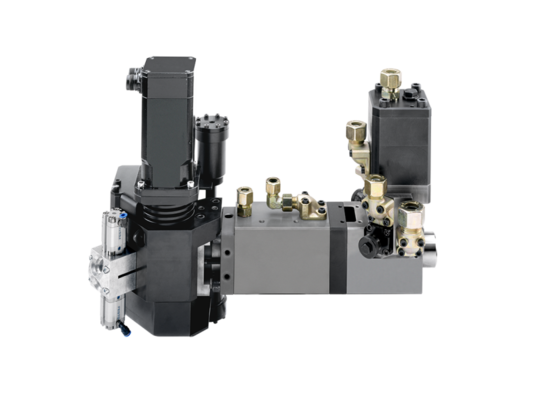

In the automated CCM (Clear Coat Molding) process, high-quality components are flooded with a transparent two-component PUR system. The CCM mixing heads ensure optimum temperature control of the raw materials. Even small discharge quantities are perfectly mixed and fed into the cavity without bubbles.

In a ColorForm application, coloured PUR or PUA coatings are applied in a closed mould.

Key features of the ColorForm CCM mixing head

- Filling process with perfect mixing for optimum component quality

- High reliability and durability

- High flexibility in nozzle technology

- Self-cleaning, maintenance-friendly design

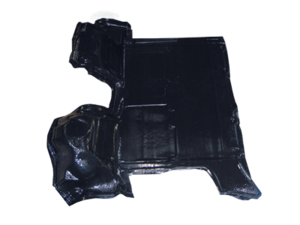

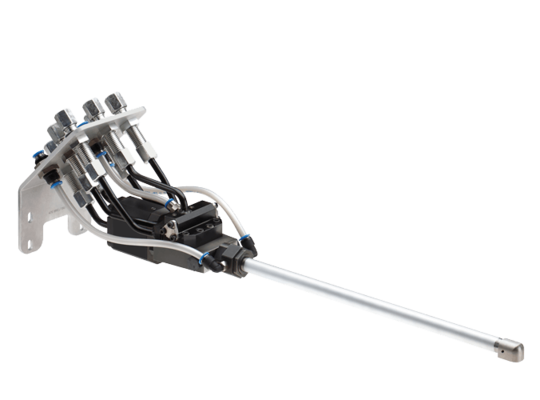

The LFI-PUR Long Fiber Injection Polyurethane process is used to manufacture high-strength lightweight components. The LFI process unit has three essential tasks that are crucial for the quality of the end products:

Core properties of long fiber injection (LFI) Mixing head

- Conveying and cutting the roving

- Mixing the reaction components

- Wetting the reinforcing fibers with the reactive mixture

- Adjusting the fiber quantity and length as required

- Flow-optimized geometry of the cleaning piston

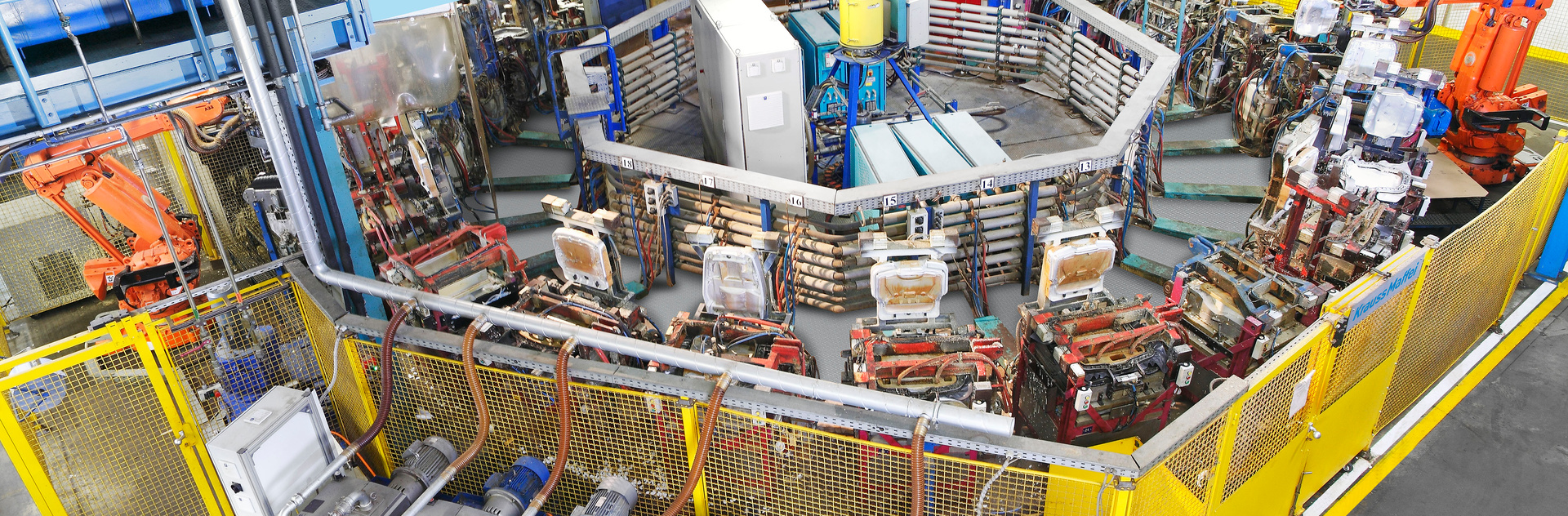

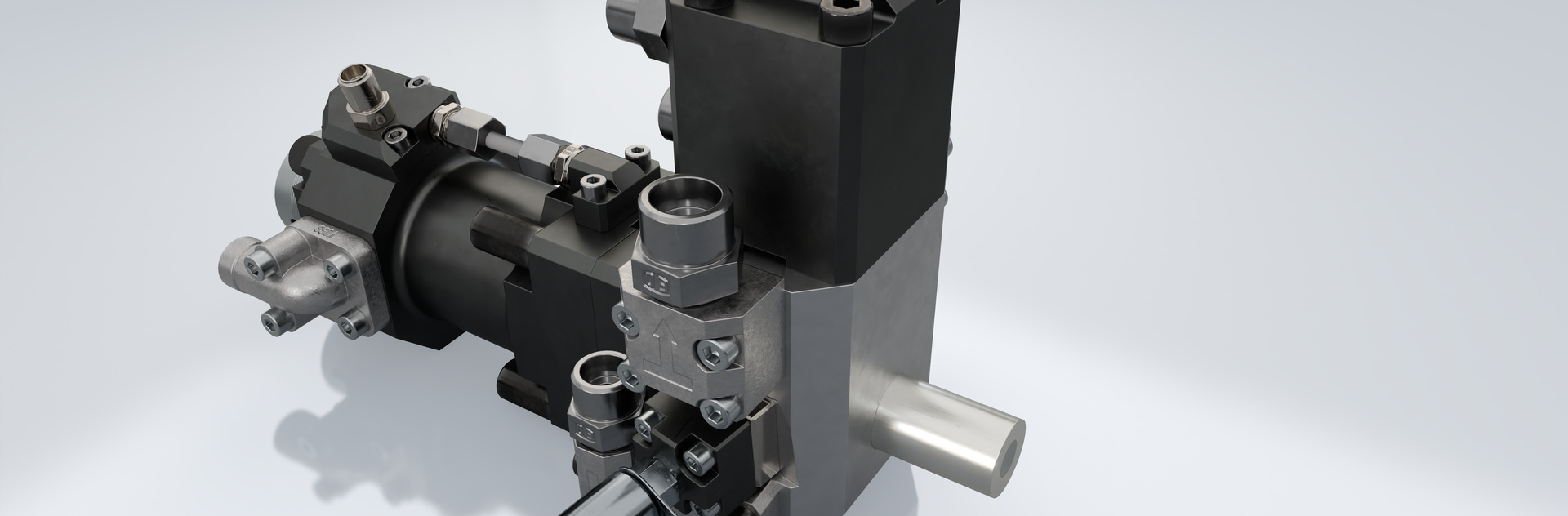

This compact and highly efficient linear mixing head is suitable for processing fast resin systems in the HP-RTM process with high-pressure mixing for the production of lightweight and high-strength components.

Core features of the resin transfer molding RTM mixing head

- High degree of process reliability and repeatability

- Production of high-strength components in large quantities

- Production of excellent surfaces

- Can be used at high mold temperatures

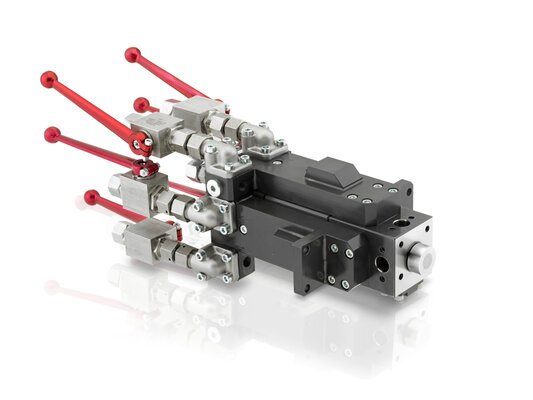

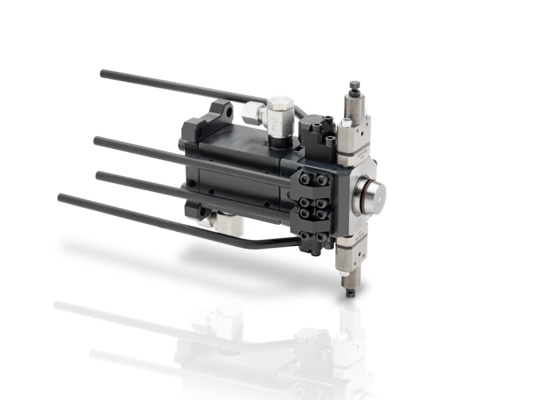

High-pressure deflection mixing head with 2 separate mixing chambers and one outlet pipe.

Our low-pressure mixing head offers an economical solution for applications with small shot quantities and low investment requirements. Mixing is carried out by a rotating agitator at pressures below 10 bar – ideal for difficult-to-mix systems and precise dosing from 0.5 g/s.

Particularly suitable for niche processes where flexibility and simple system technology are paramount.

Key features of the low-pressure mixing head

- Easy option to run 2 different components one after the other

- Quick change between 2 systems in one system

- Easy control and integration into existing systems

- All the advantages of our deflection mixing heads