Petrochemical

Product information

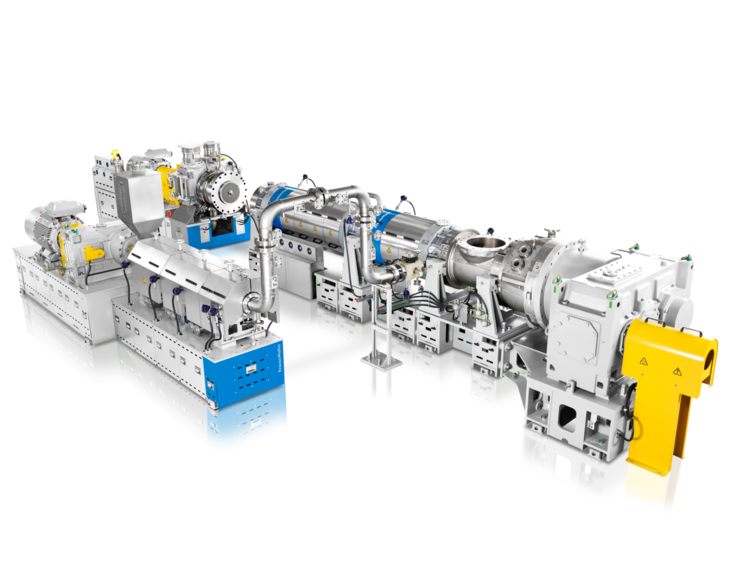

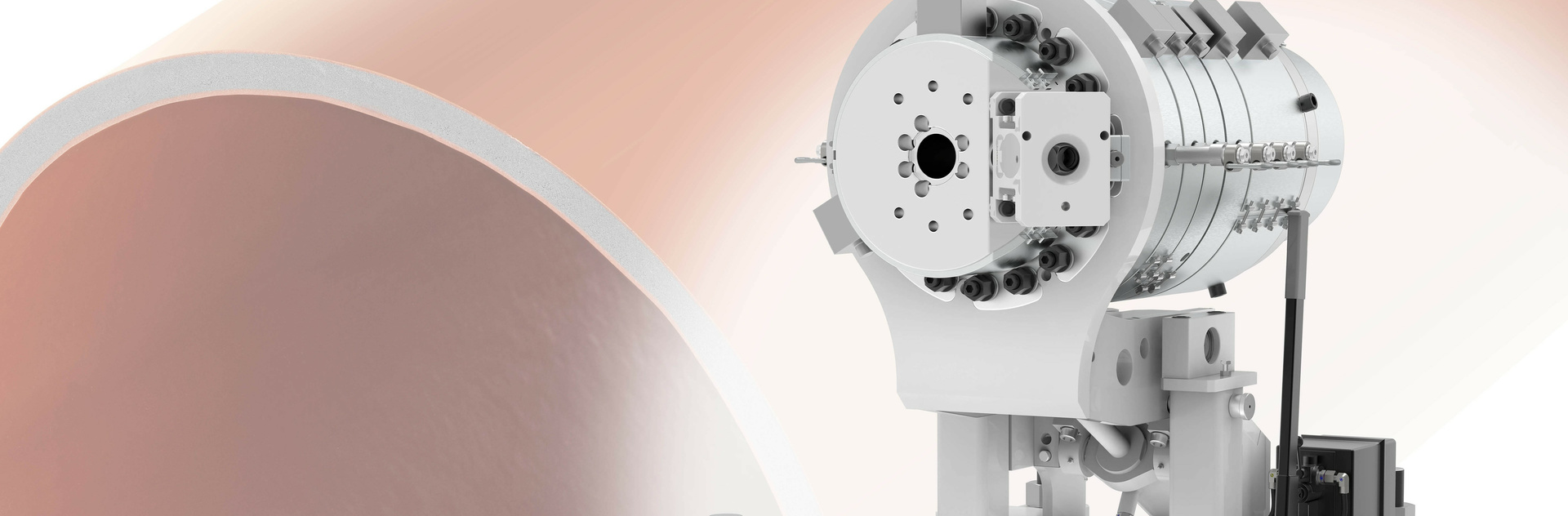

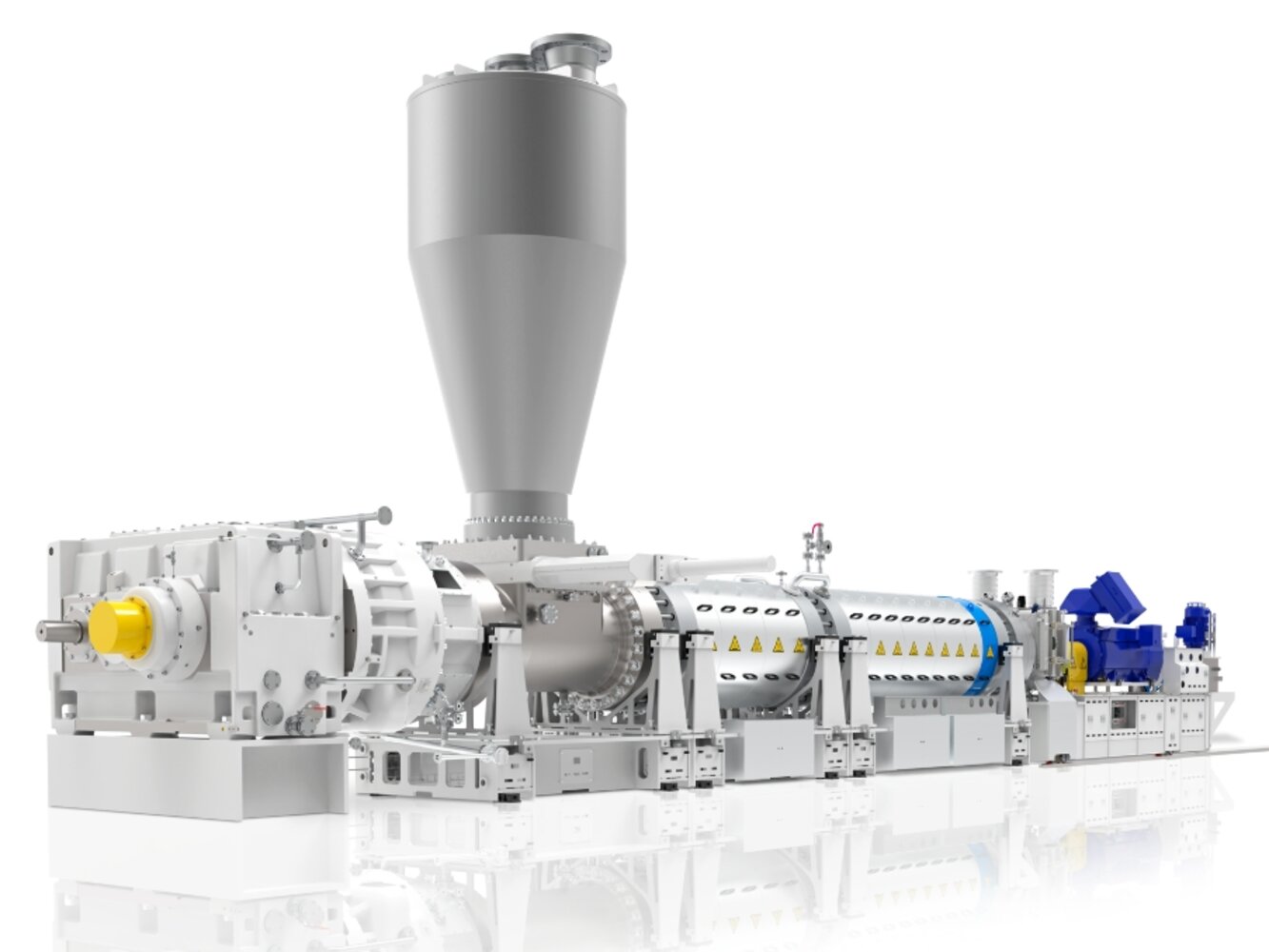

KraussMaffei Extrusion KE single-screw extruders are versatile machines used for a wide range of thermoplastic processing tasks. A common application is their use as melt pumps to build up the necessary pressure for pelletizing. In this role, the KE series offers a key advantage over other methods: it combines high pumping efficiency with minimal energy loss from melt heating, making it both powerful and energy-efficient.

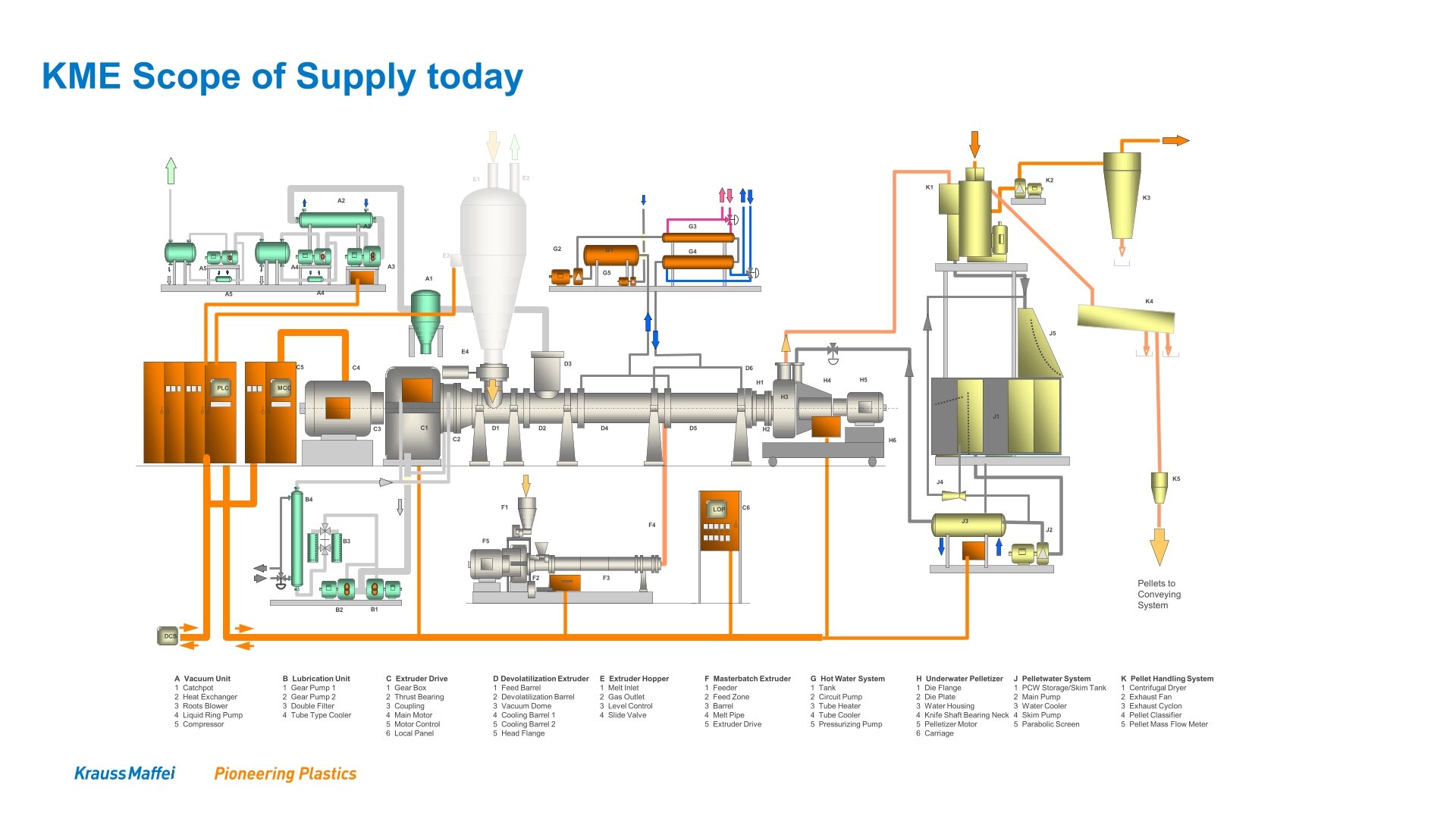

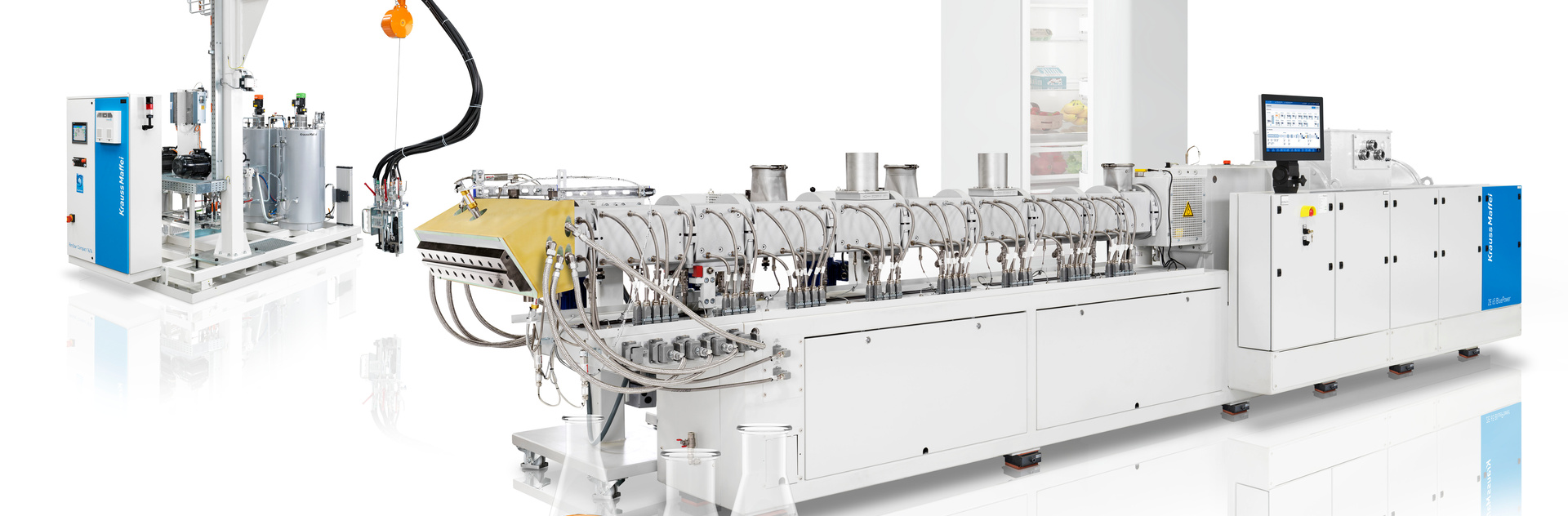

KraussMaffei Extrusion offers time-tested & state-of-the-art machinery for virgin polymer producers worldwide. With extensive know-how in engineering, manufacturing and safe commissioning of extrusion lines for the petrochemical industry, we are a proven and strong partner to our customers. Especially in this field, reliability, uptime and competent support are obligations for the profitability of your enterprise. With our large-scale single (KE series) and twin-screw extrusion lineup (BP and PC series) we can offer efficient tailored solutions for any process demand: novel or established, through licensors, EPC contractors or directly.