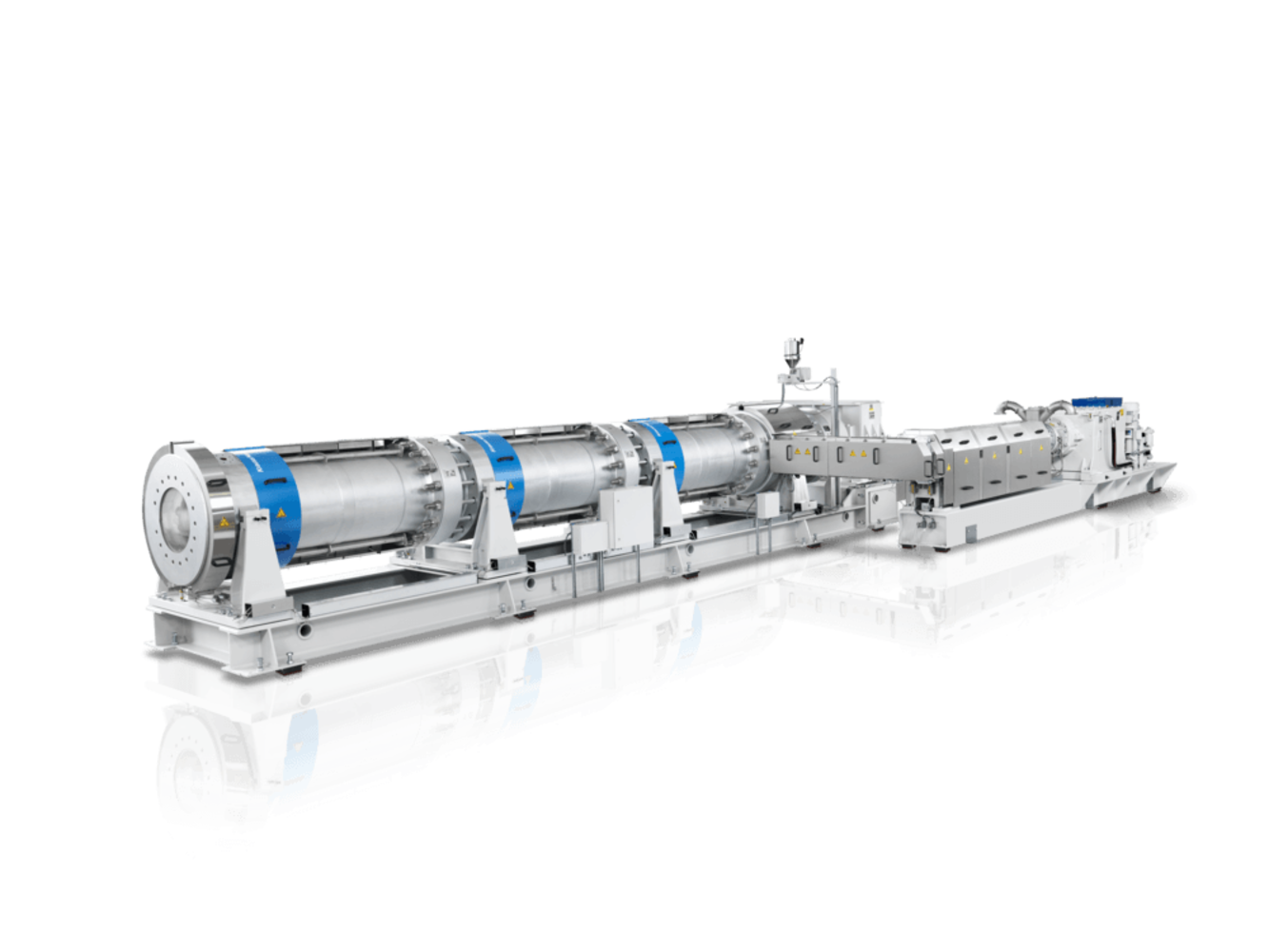

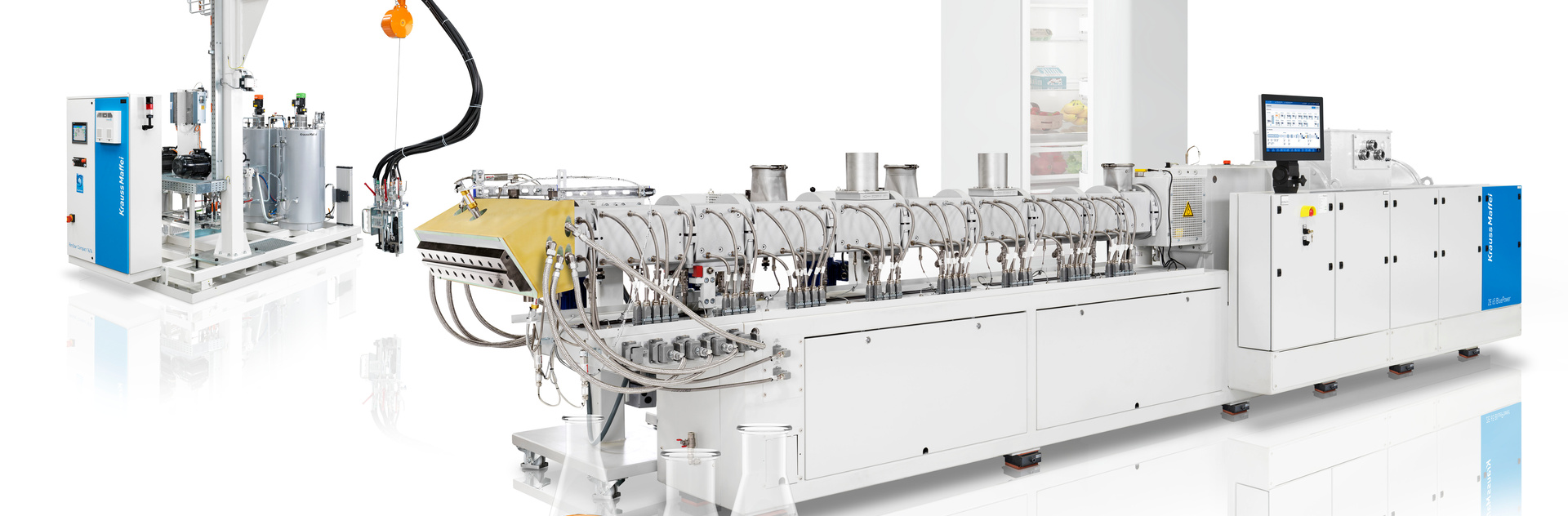

Schaumex and Schaumtandex lines are among the most successful systems worldwide for enhancing productivity and cost-effectiveness in foam extrusion. In addition to cutting-edge extrusion technology, process engineering expertise and unique plant engineering competence are key factors in the implementation of these solutions.

Premium quality and maximum reliability: to stand the test of time and ensure long-term business success, foam extrusion lines must meet the most demanding requirements. Drawing on the experience gained from several hundred Schaumex and Schaumtandex lines delivered to customers around the globe, KraussMaffei Extrusion has developed concepts that set new standards in the production of foamed boards, foamed sheets, foam tubes, and particle foams.