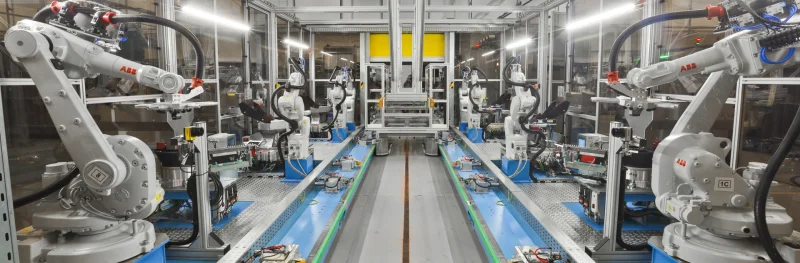

Crocodile mold carrier

Efficiency Meets Precision

Product information

KraussMaffei’s Crocodile Mold Carriers set new standards in the production of armrests and door panels. With state-of-the-art drive technology, intelligent design, and high process reliability, they enable economical and flexible manufacturing – ideal for OEMs and Tier 1 suppliers.

- Decentralized HMI control for intuitive operation and maintenance

- Easy mold changes due to well-thought-out carrier design

- Short tool closing times thanks to powerful e-drives

- Servo-electric drives for excellent dynamics and precise positioning

- Free pivoting of tools for optimal foam distribution

Advantages that make the difference.

< 2 seconds

Closing time

-10° to +30°

Tool tilting angle

34 kN

Clamping force

Use cases

Industries

Automotive