Plan your success in the race for the automotive competitive edge in large-scale production and in all other areas. Do it with a system partner that has been dealing with everything that moves the automotive industry ahead in the area of plastics and rubber processing for decades.

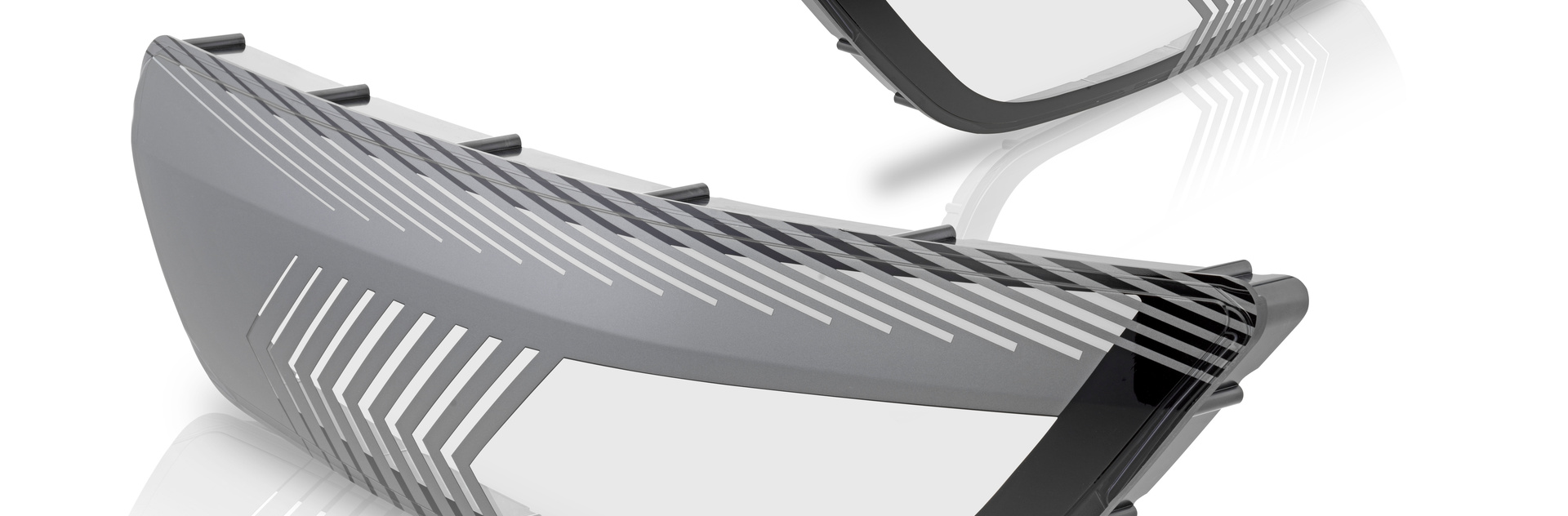

From large-format, contoured bumpers, intricate lenses and fiber optics to multifunctional components in the engine compartment to premium quality visible parts in the interior and exterior in the injection molding process. From composites for lightweight construction in e-mobility, to polyurethane components for seats, headrests and interior surfaces with an excellent look and feel, to complete solutions for battery manufacturing. Or in extrusion, for manufacturing sealing profiles for targeted drainage of rainwater, or tire parts for tires with low rolling resistance.

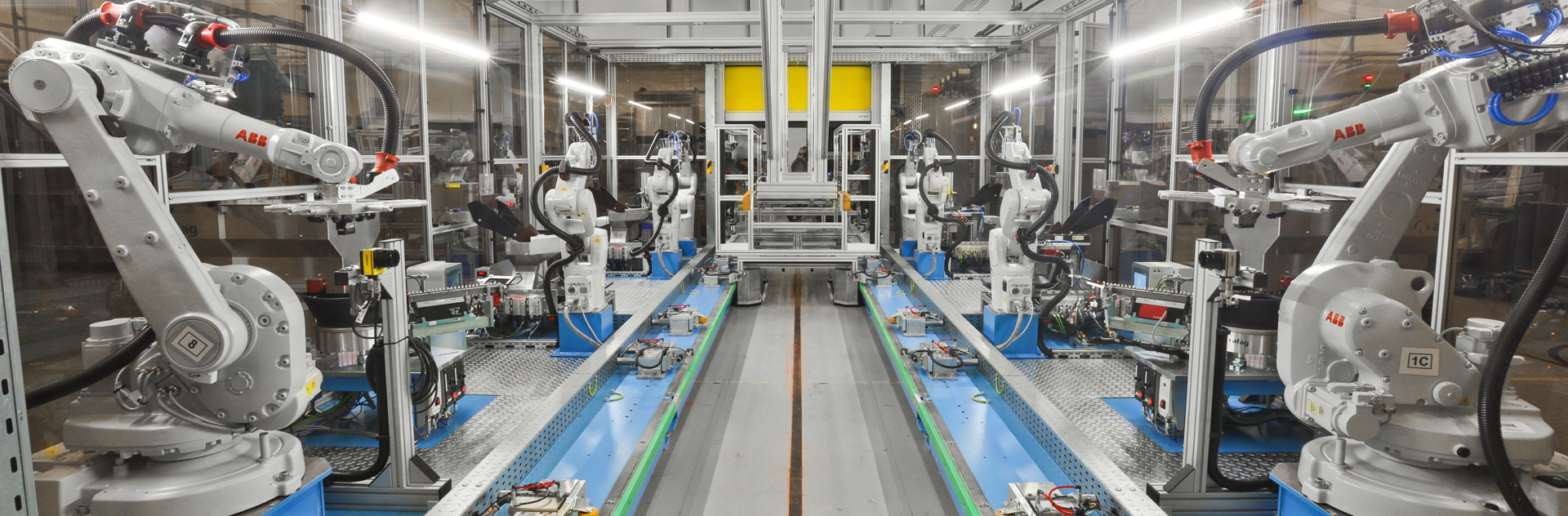

KraussMaffei achieves top quality for you with maximum availability and process stability. You get everything from a single supplier and benefit from experts and synergies from all three technologies: Injection Molding Machinery, Reaction Process Machinery and Extrusion Technology. In combination with our automation and digital solutions, we supervise your manufacturing process reliably and over the long term.

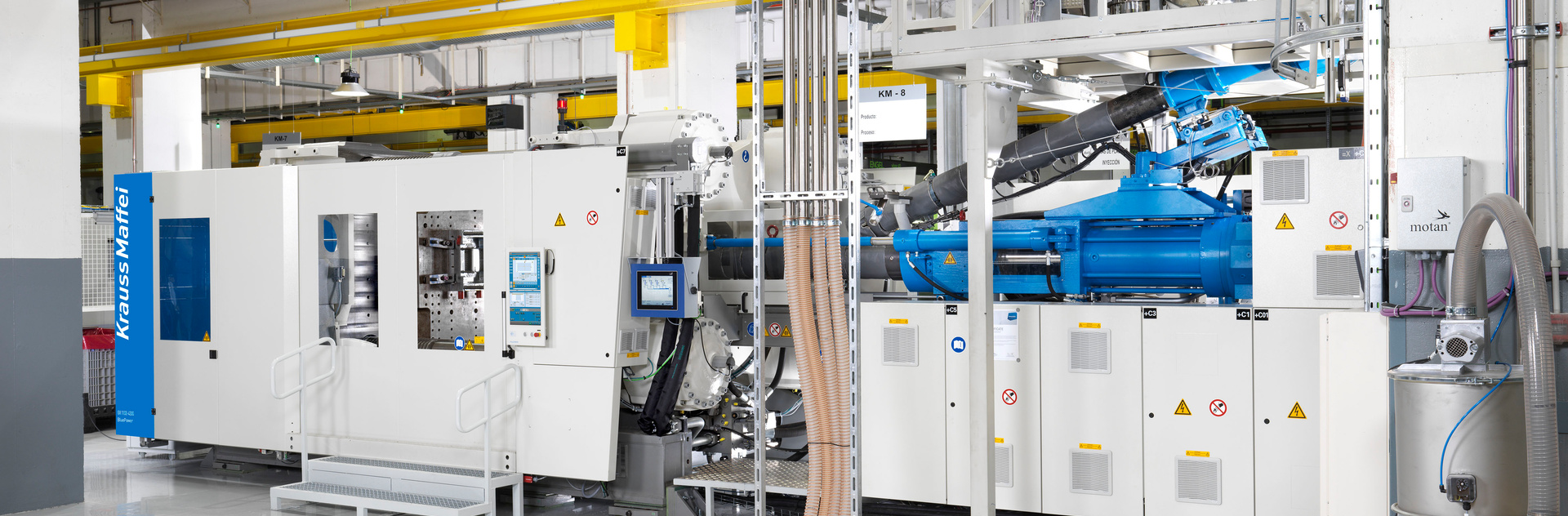

Step into the future with us. In our innovation centers, we work together with you to develop the optimal solution for you for cost-effective, energy-efficient and resource-saving high-performance series production. We combine detailed specialized knowledge with extensive experience and the use of premium quality recycled materials so that you can produce top quality with maximum throughput.