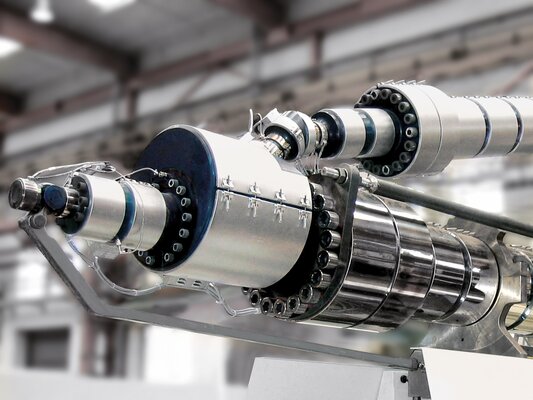

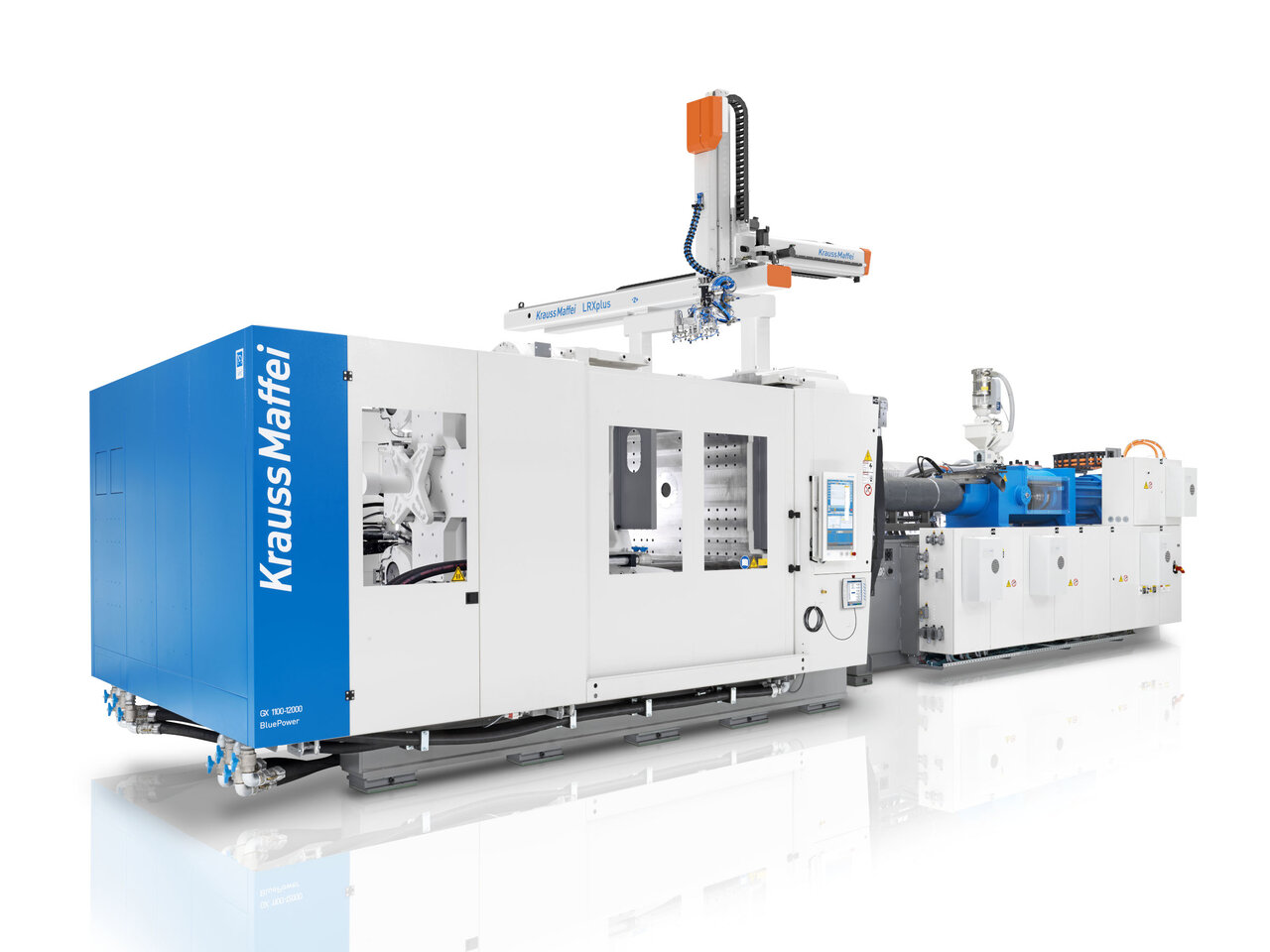

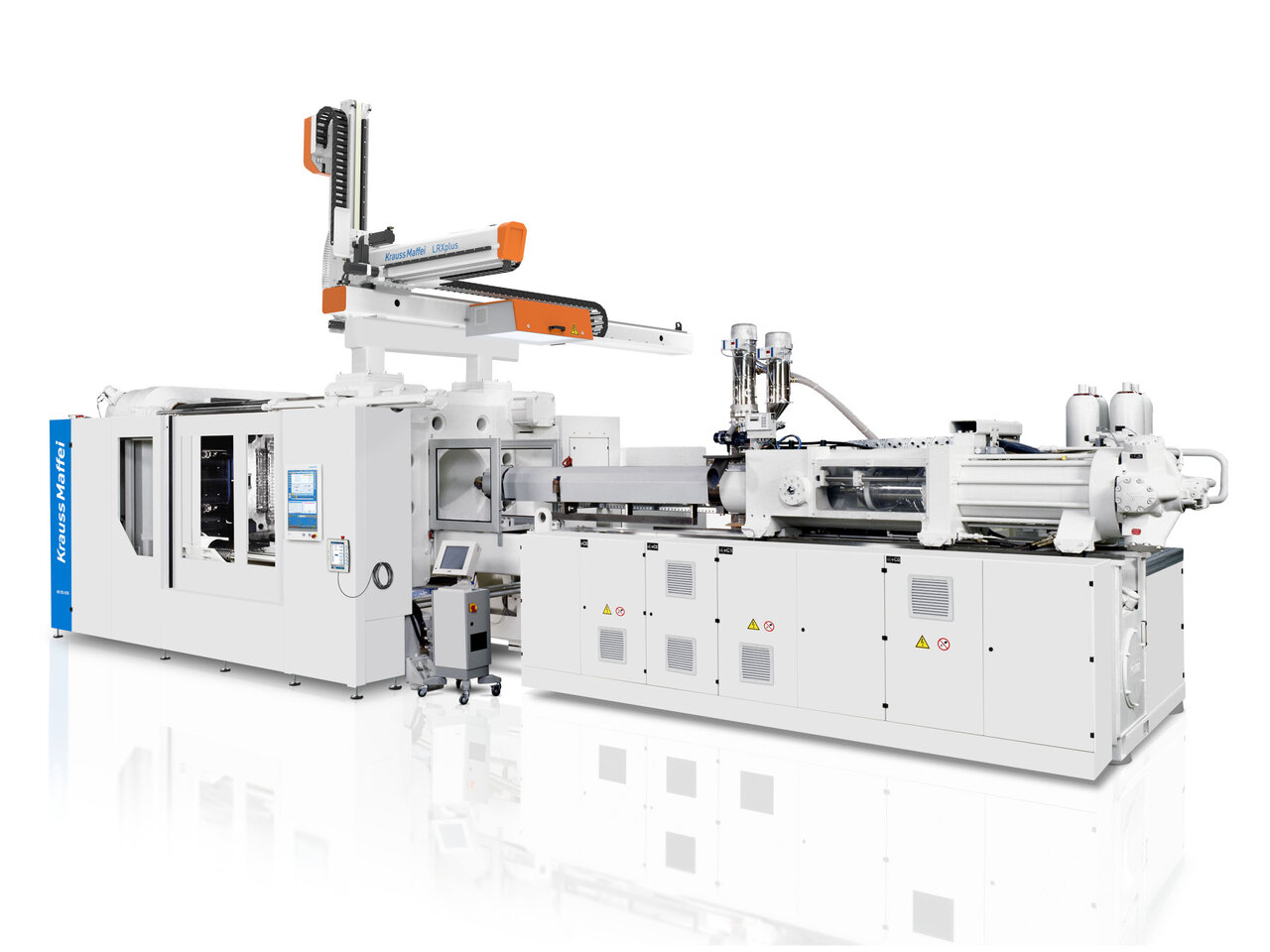

Multinject

Added value through more components

Product information

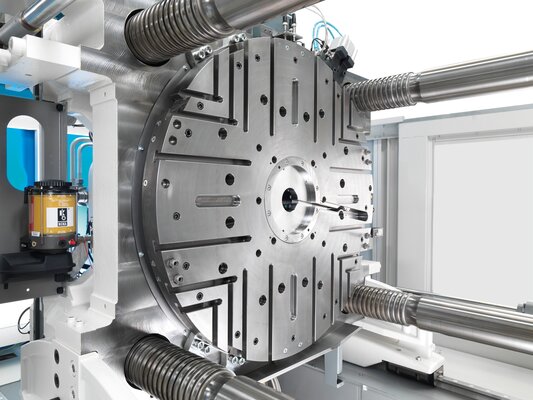

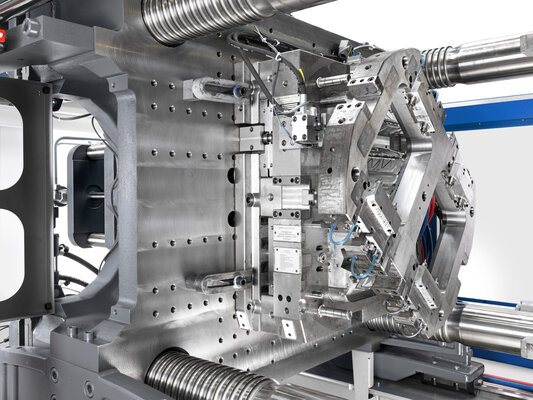

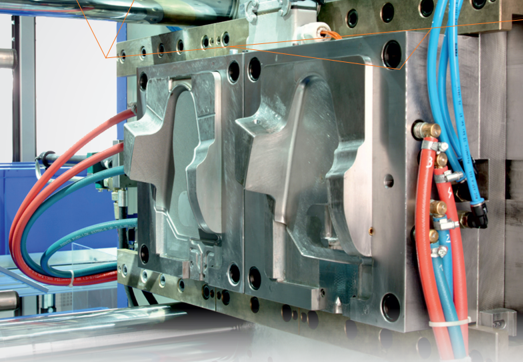

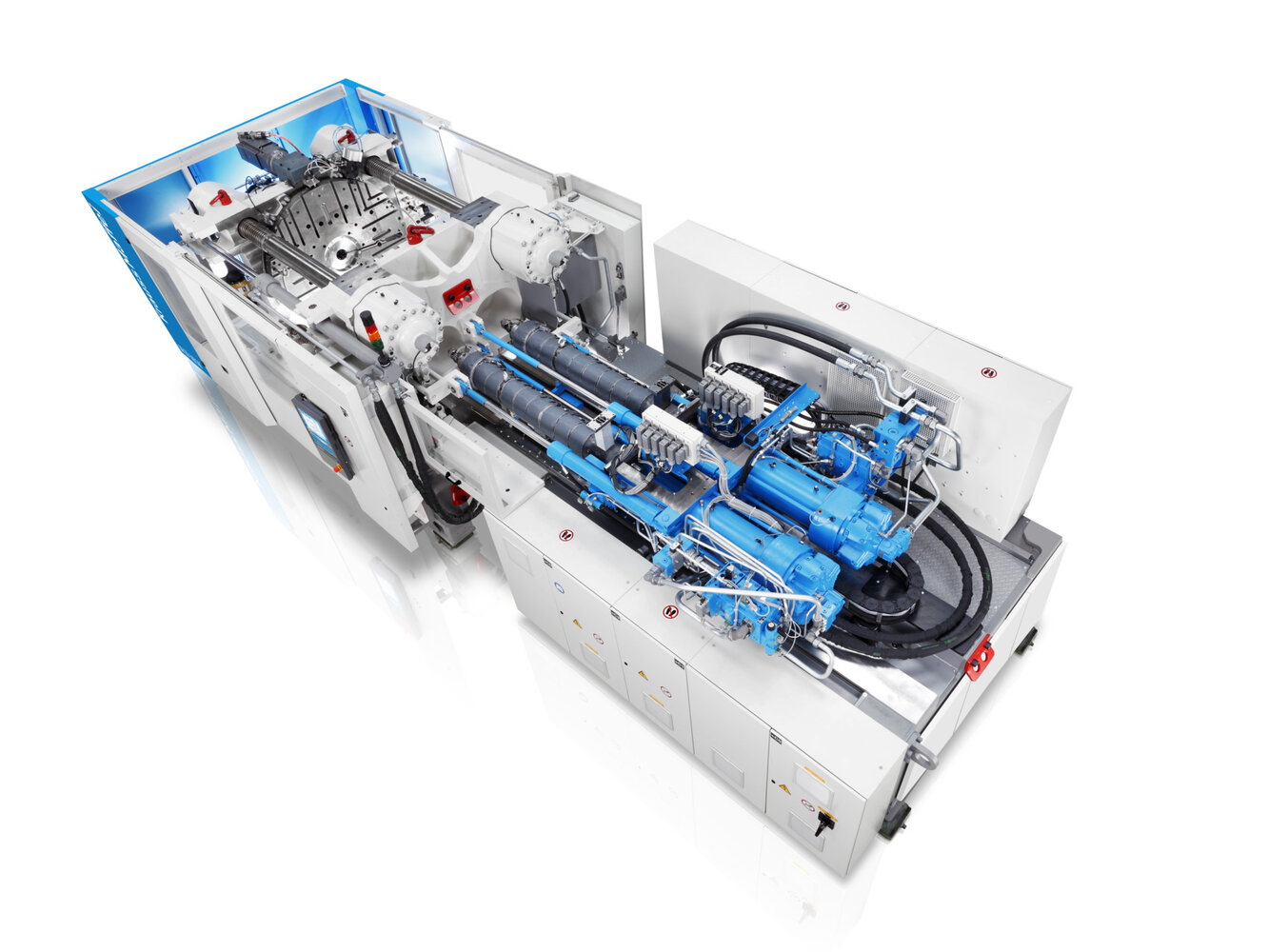

KraussMaffei's Multinject technology provides you with the correct system solution consisting of different injection molding variants and mold technologies for your product.

- Excellent functional integration

- Combined material properties

- Integrated work steps

- Improved quality

- Great design freedom