FiberForm-Technology

Thermoplastic lightweight construction

Product information

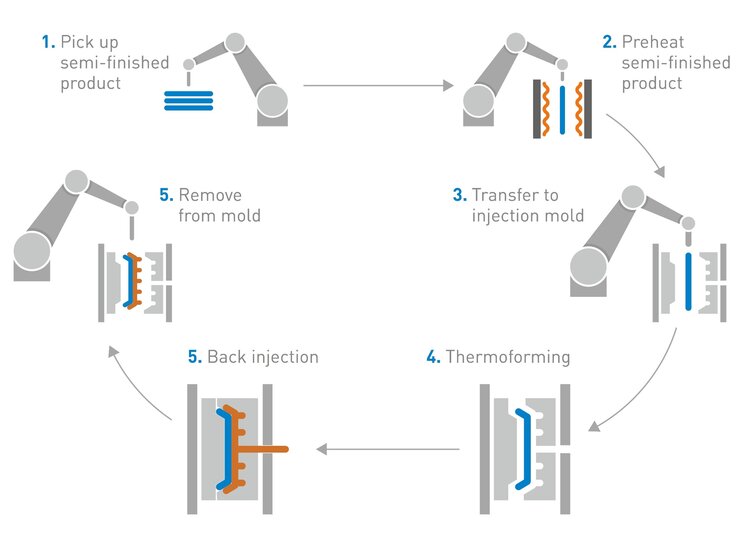

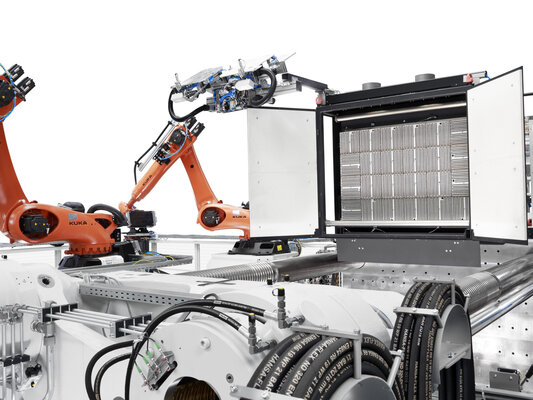

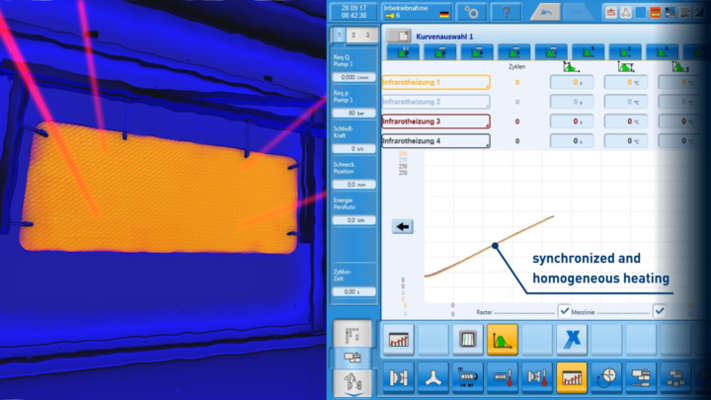

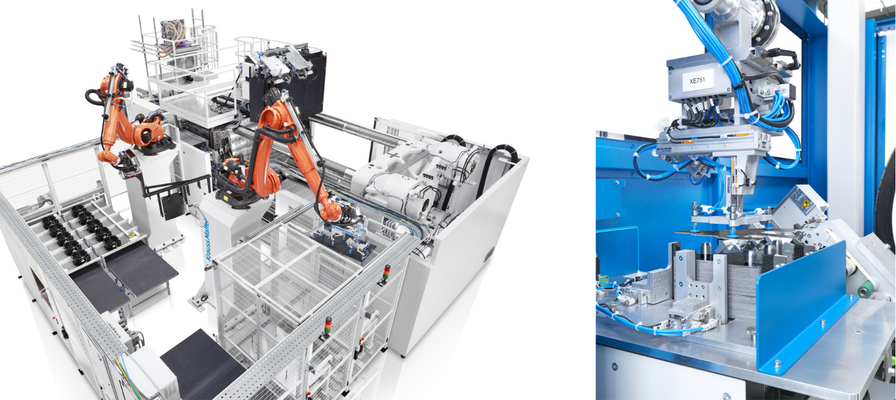

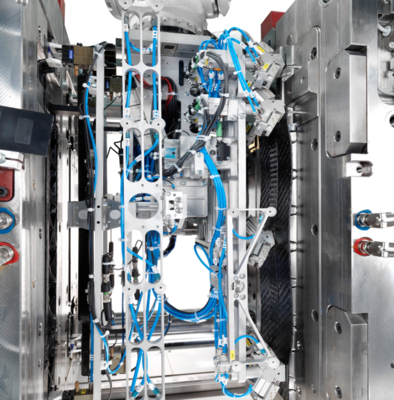

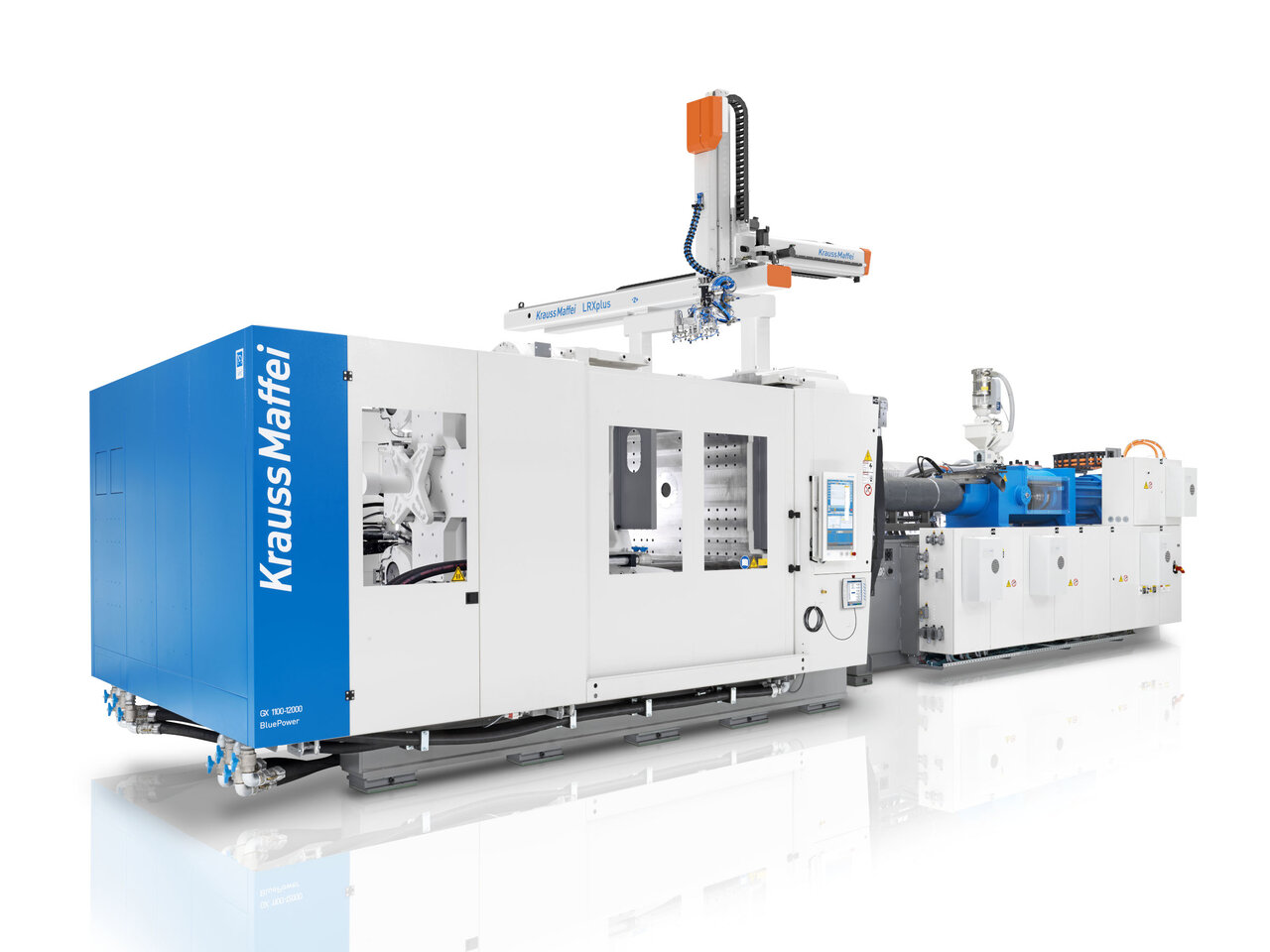

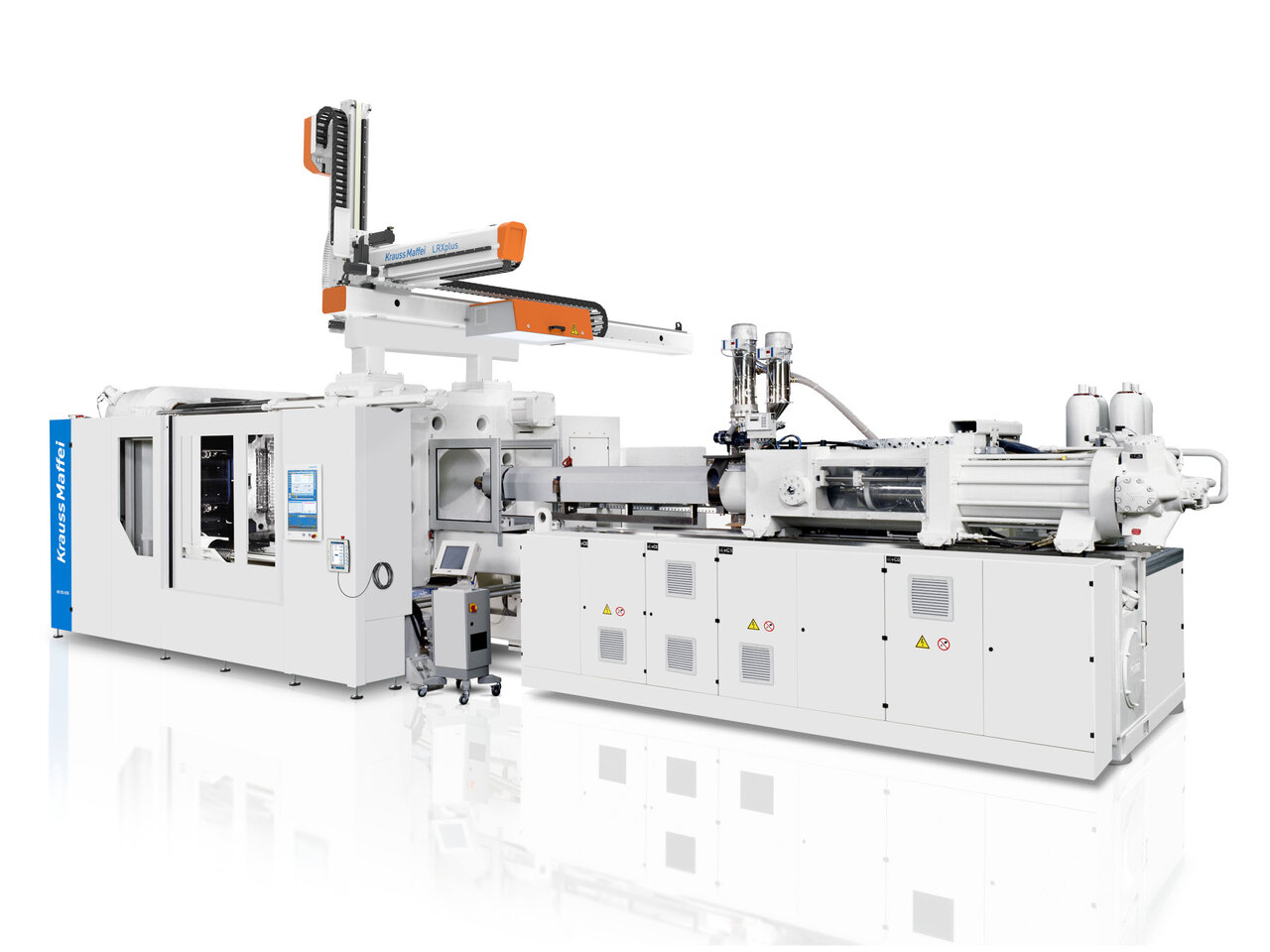

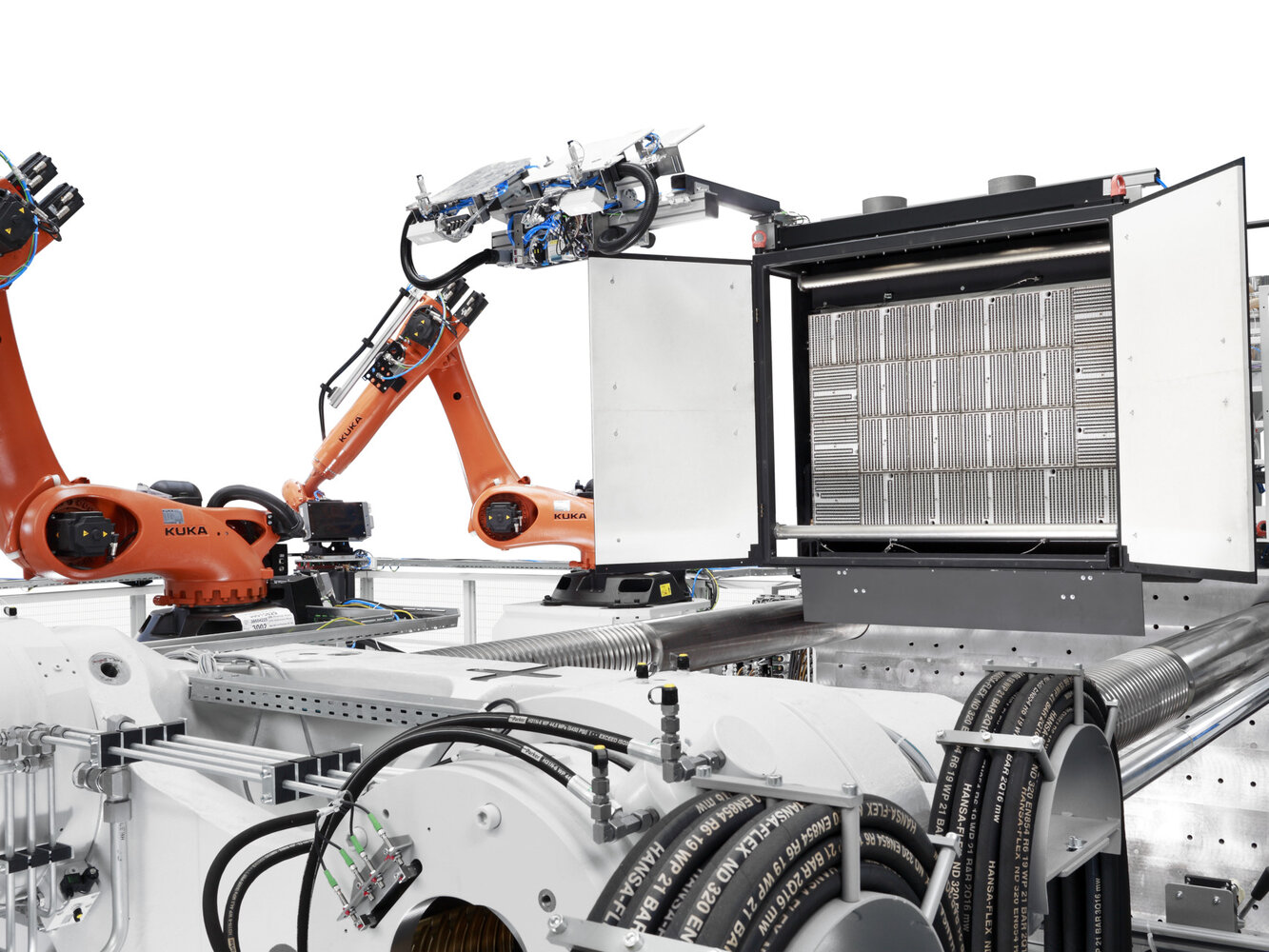

The FiberForm process is a lightweight construction process and uses organic sheets or UD tapes as semi-finished products in the injection molding process. These inserts consist of a thermoplastic matrix usually impregnated with glass or carbon fiber fabric and are fed via an automation solution, preheated in an oven and then formed in the mold by the clamping movement and then back-injected with plastic. In this way, high-strength, specifically reinforced molded parts are produced that offer a significant weight advantage compared to metal components, for example.