PolySet Technology

Polyester processing - Advanced cross-linked parts

Product information

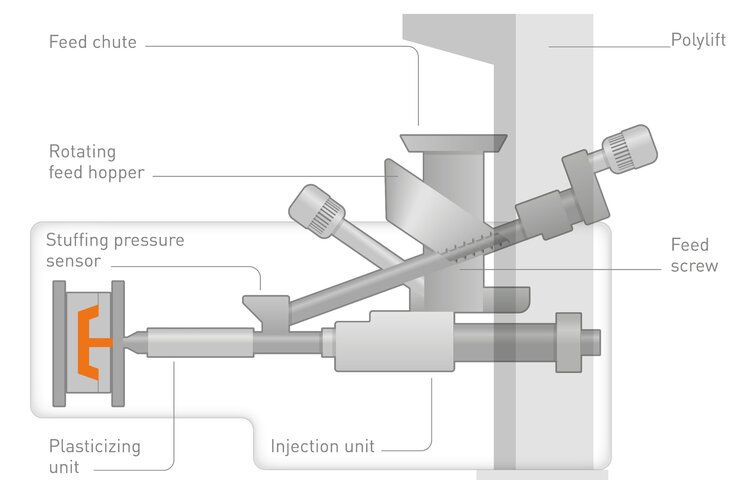

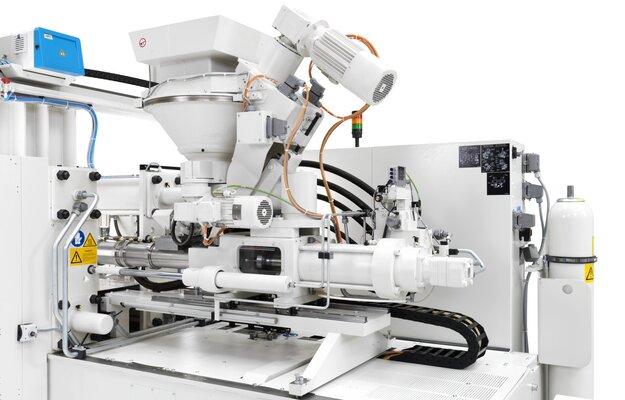

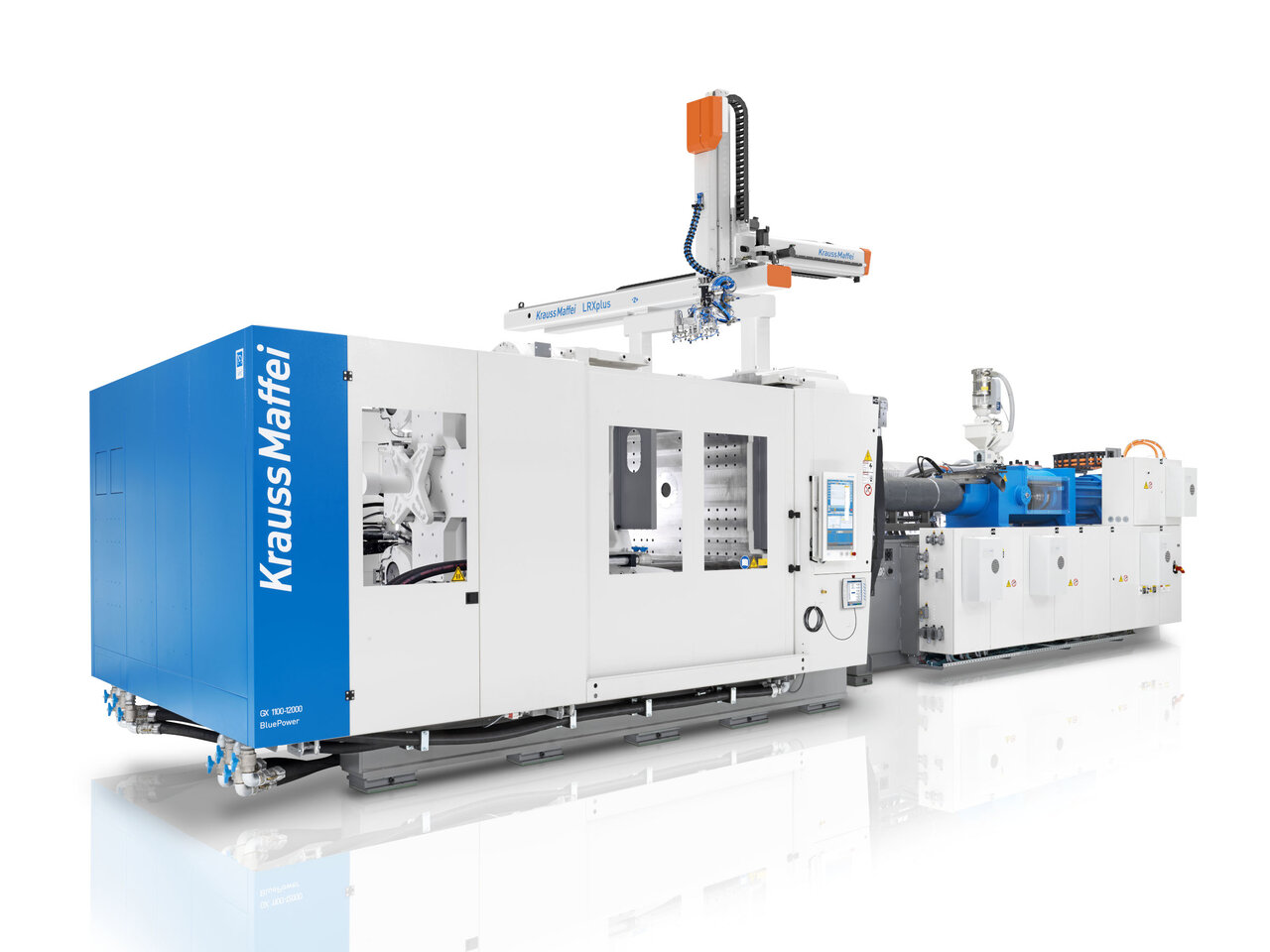

With PolySet technology, we can offer the processing of thermosets in the form of doughy polyester or vinyl ester compounds into high-quality technical components. In contrast to thermoplastics, thermosets cannot be remelted. Thermosets react irreversibly when heat is applied in a hot mold. Adapted machines and processes are required to process these reactive molding compounds. Even the condition of the raw materials differs significantly from the granulates commonly used for thermoplastics.The processing parameters also differ greatly from the usual values for thermoplastics. For example, the tools are usually electrically heated to 150 - 200 °C, while the plasticizers are tempered or cooled with water or heat transfer oil.