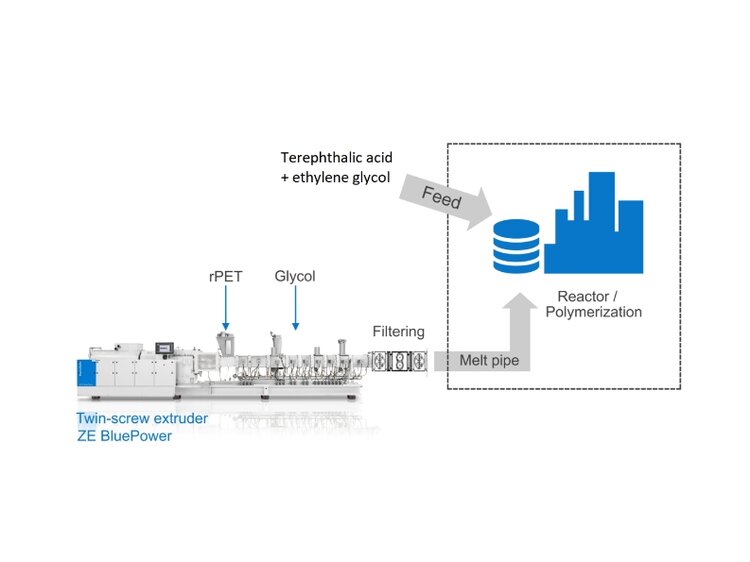

PET is the flagship material of the circular plastics economy: consistently available, low in variability, and reactive for re-condensation. Our ZE BluePower twin-screw extruder offers a fully scalable system (20–12,000 kg/h) for gentle melting, effective moisture removal, and short residence times, preserving intrinsic viscosity and making the material fully reusable for preform production.

Recycling

Product information

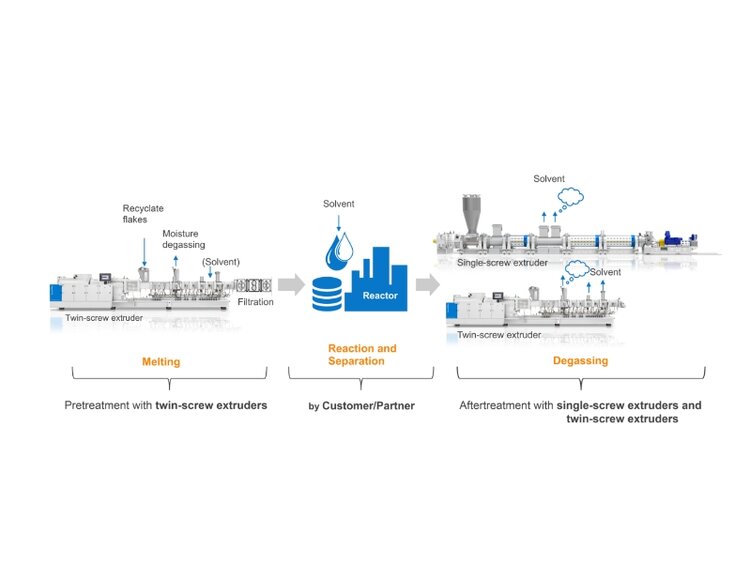

Sustainability is a key focus area at KraussMaffei Extrusion. With our proven and well-established extrusion technologies, we offer time-tested solutions for all recycling process requirements, especially for challenging applications that demand high quality and high throughput, or involve novel technologies. As an independent systems provider, we can select the optimal equipment for your specific needs, supported by a team of experts dedicated to turning your ideas into reality.