SilcoSet Technology

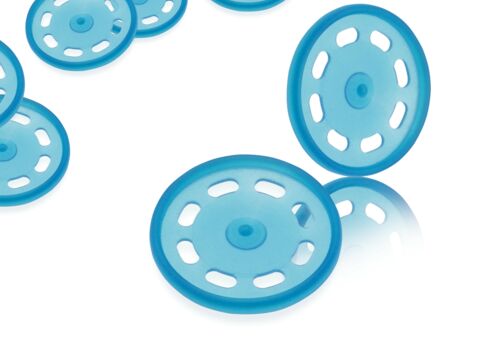

Silicone processing (LSR + HTV) - More with elastic properties

Product information

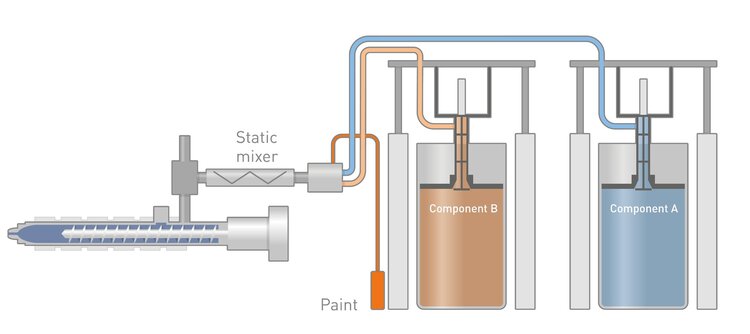

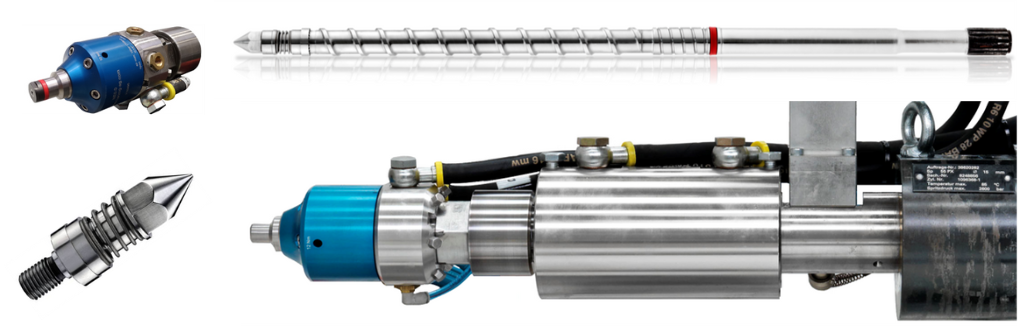

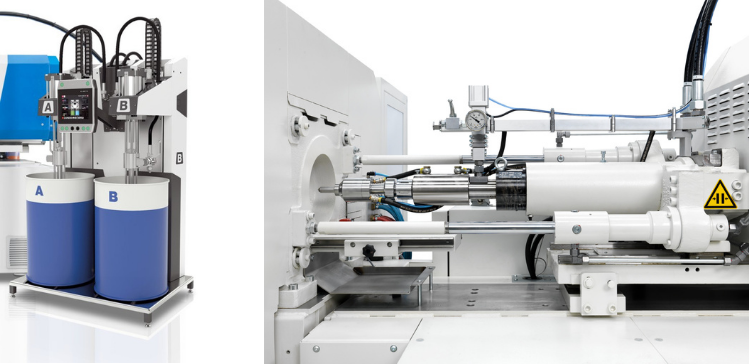

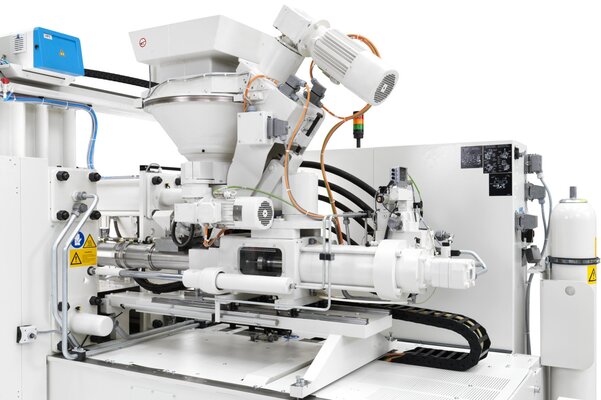

Liquid silicones (LSR - Liquid Silicone Rubber) are viscous or pasty compounds that are dosed and processed in a special plasticizing system and additional units. The mixtures are injected into a hot mold on an adapted injection molding machine, where they crosslink non-reversibly.

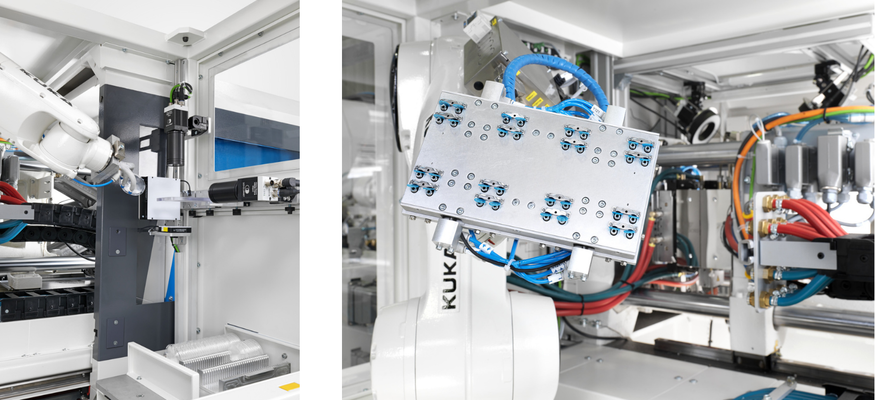

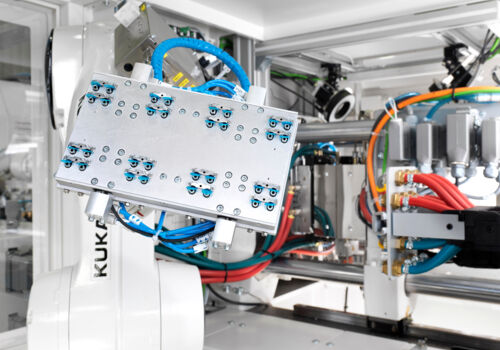

Furthermore, HTV (high-temperature crosslinking) solid silicones can be processed with our automatic feeding system (AZ system).

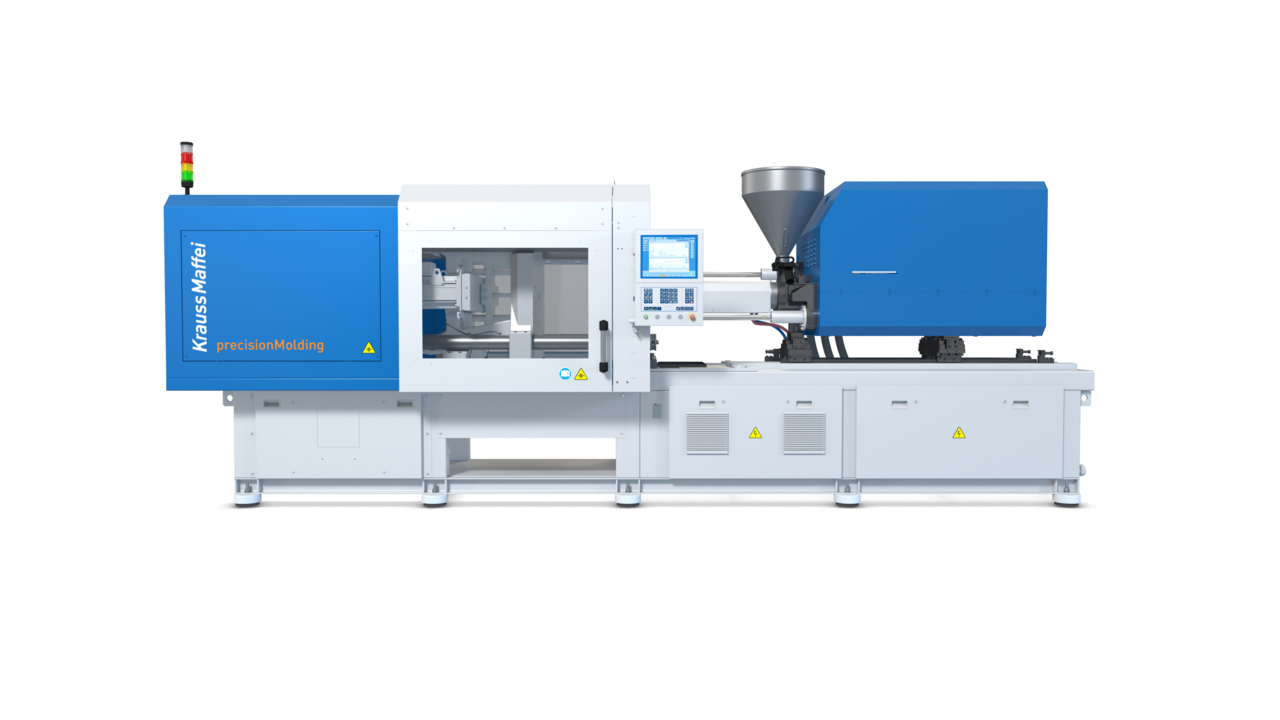

KraussMaffei offers you the appropriate machine and automation technology for the production of these elastic components based on the hydraulic CX and fully elastic PX and PA series.