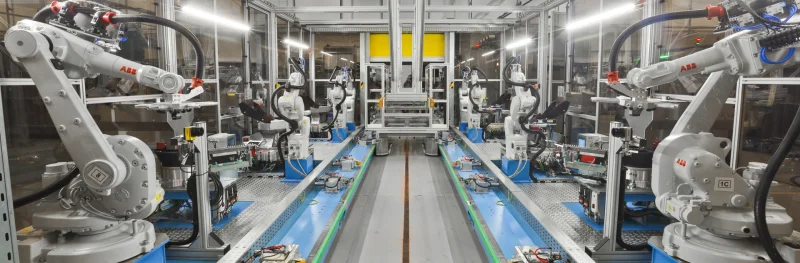

Dynamic Mold Heating (DMH)

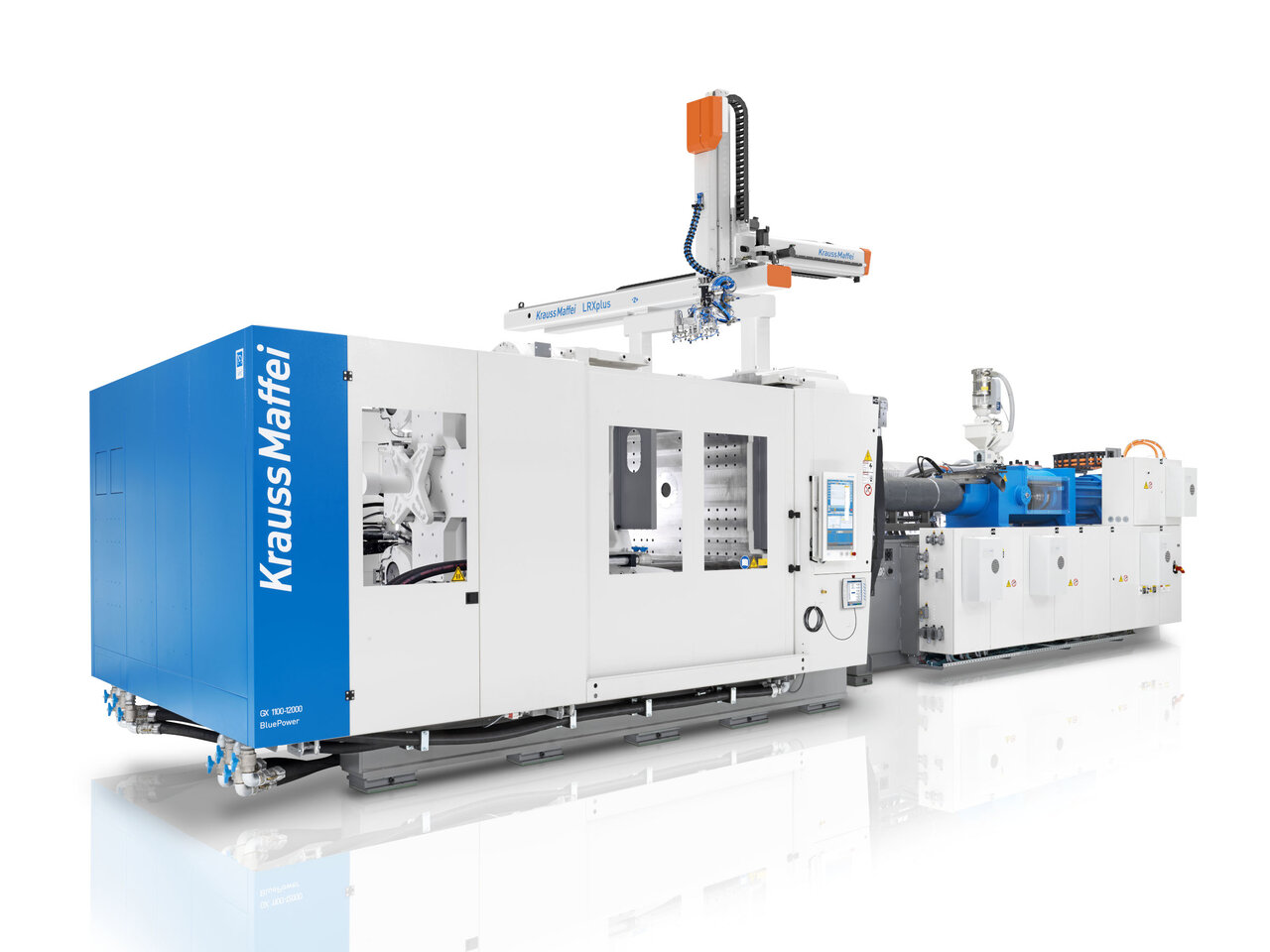

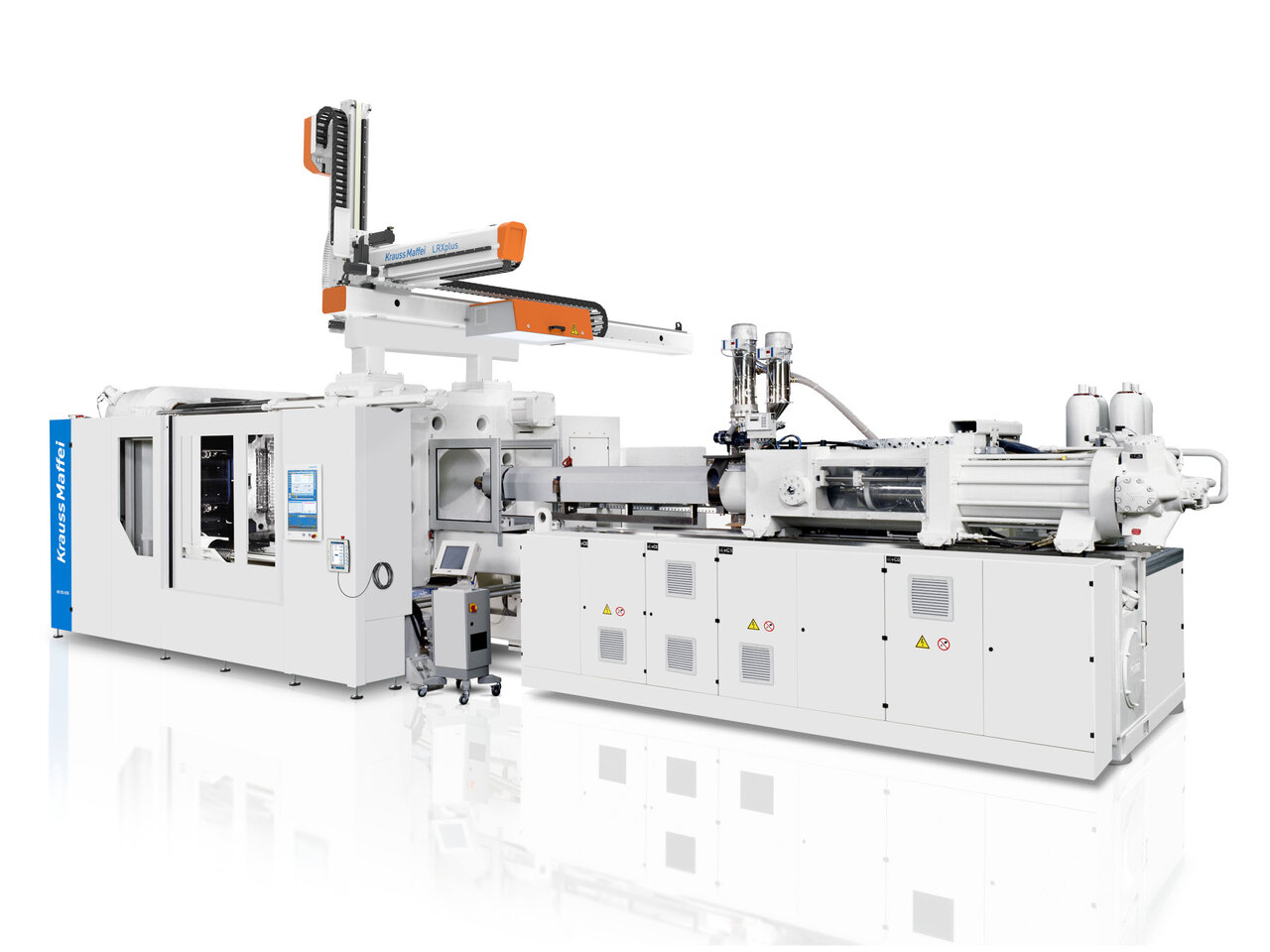

Dynamic Mold Temperature Control (Variotherm) - Powered by Heat

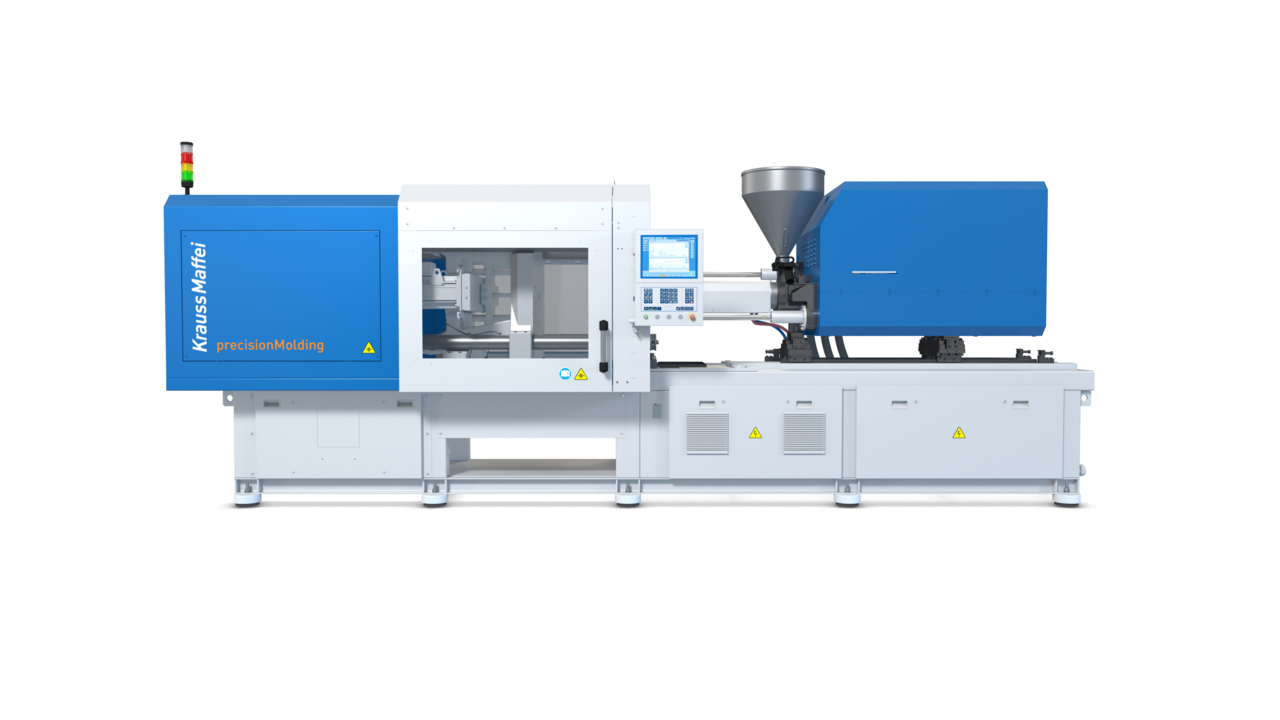

Product information

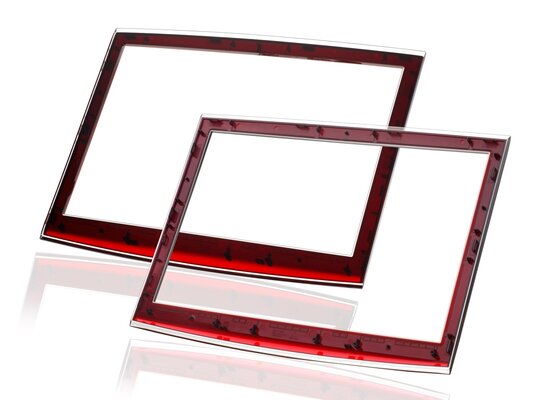

DMH (Dynamic Mold Heating) is a variothermal temperature-control process. The mold wall is intensely heated before injection and rapidly cooled again after filling. Depending on the requirement, one or both mold halves can be temperature-controlled. This process enables the production of parts with high-quality surfaces and improved properties in a single-shot process.

- Elimination of typical injection molding defects

- Creation of new, sophisticated surface designs

- Savings in material during cycle time