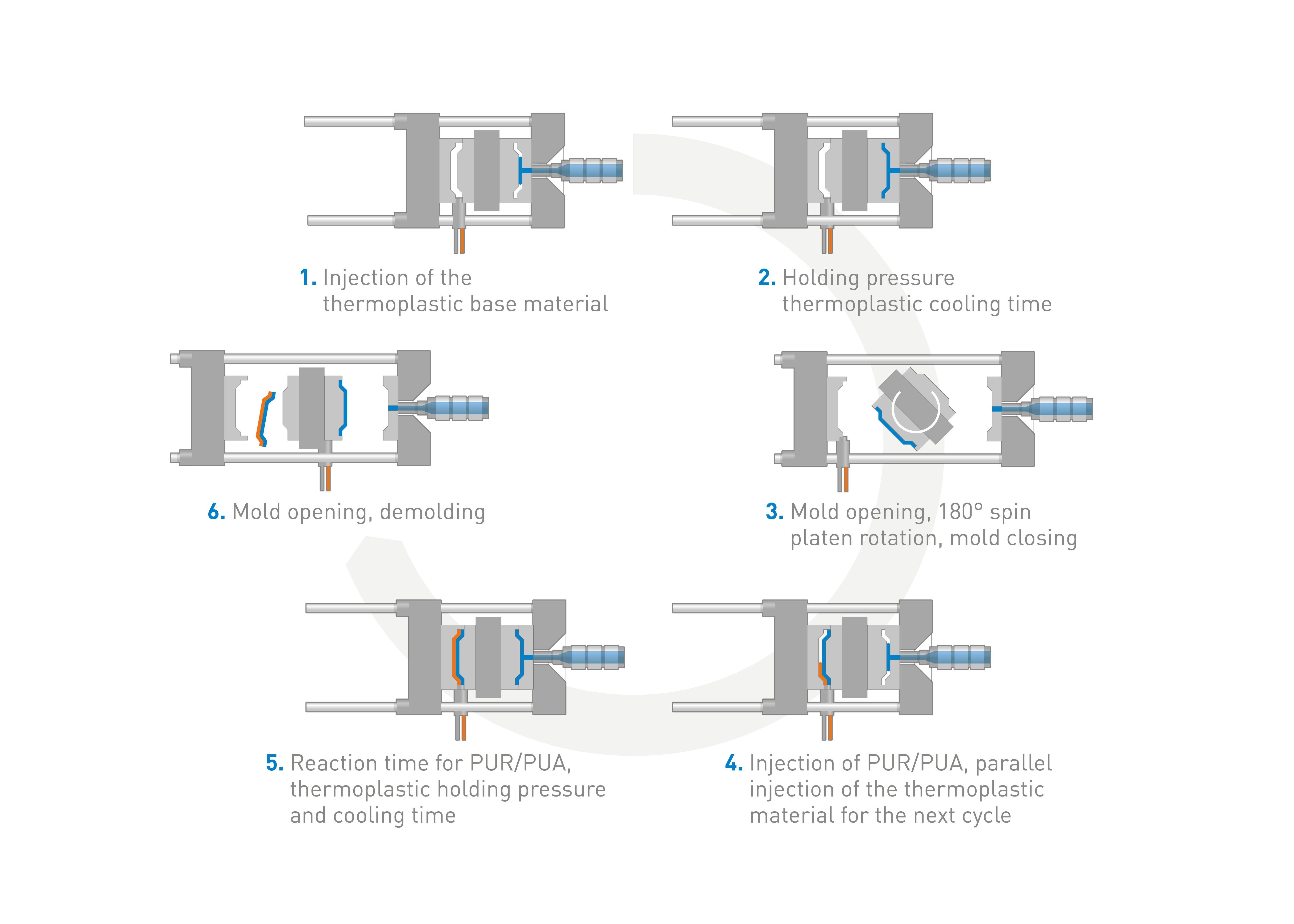

ColorForm is a multi-component injection molding process in which a thermoplastic carrier is flooded with a PUR or PUA coating system.

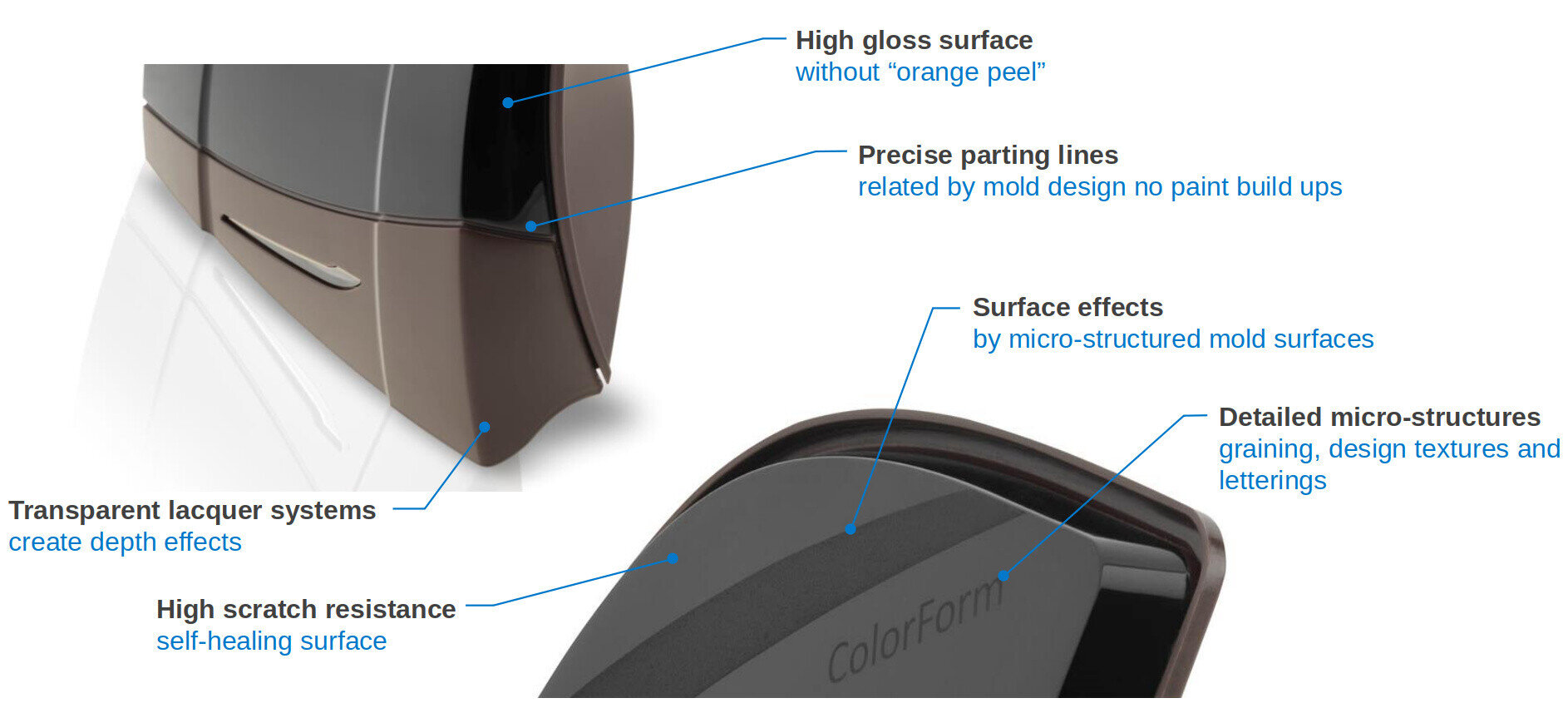

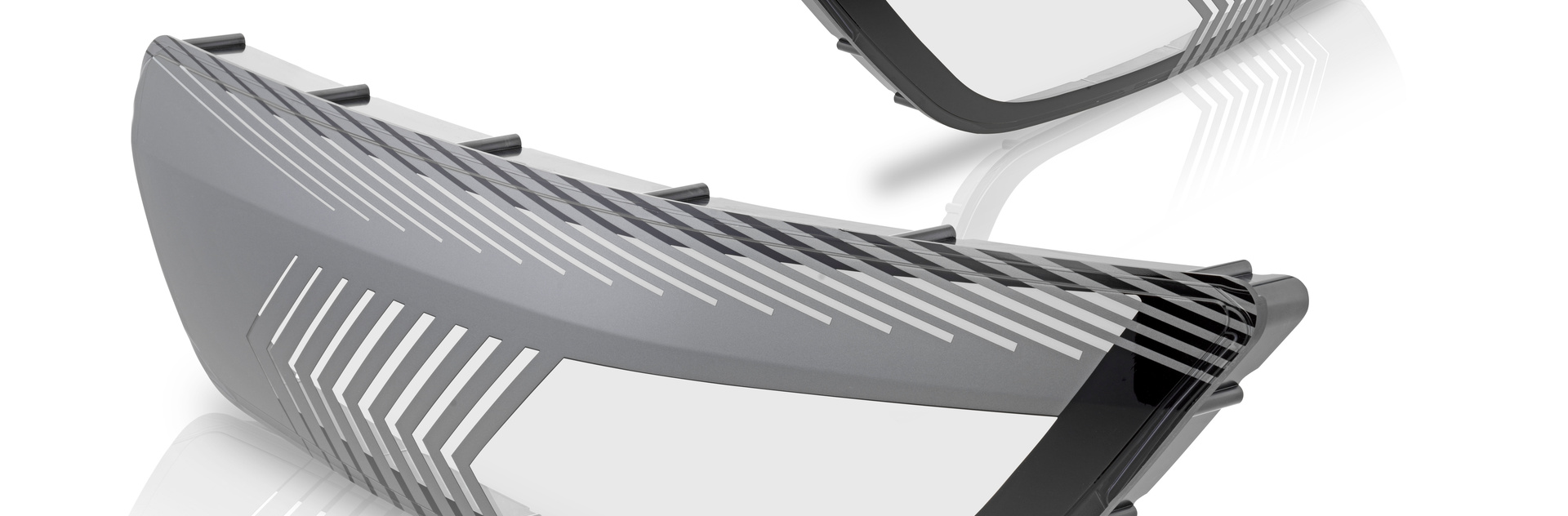

High-gloss surfaces are created in a single step with solvent-free coating systems. The color spectrum ranges from piano black to transparent. The resulting surfaces are scratch-resistant and have excellent UV resistance. Compact or lightly foamed PUR systems are used in the SkinForm process. These enable scratch-resistant surfaces with soft-touch effects in the same process.

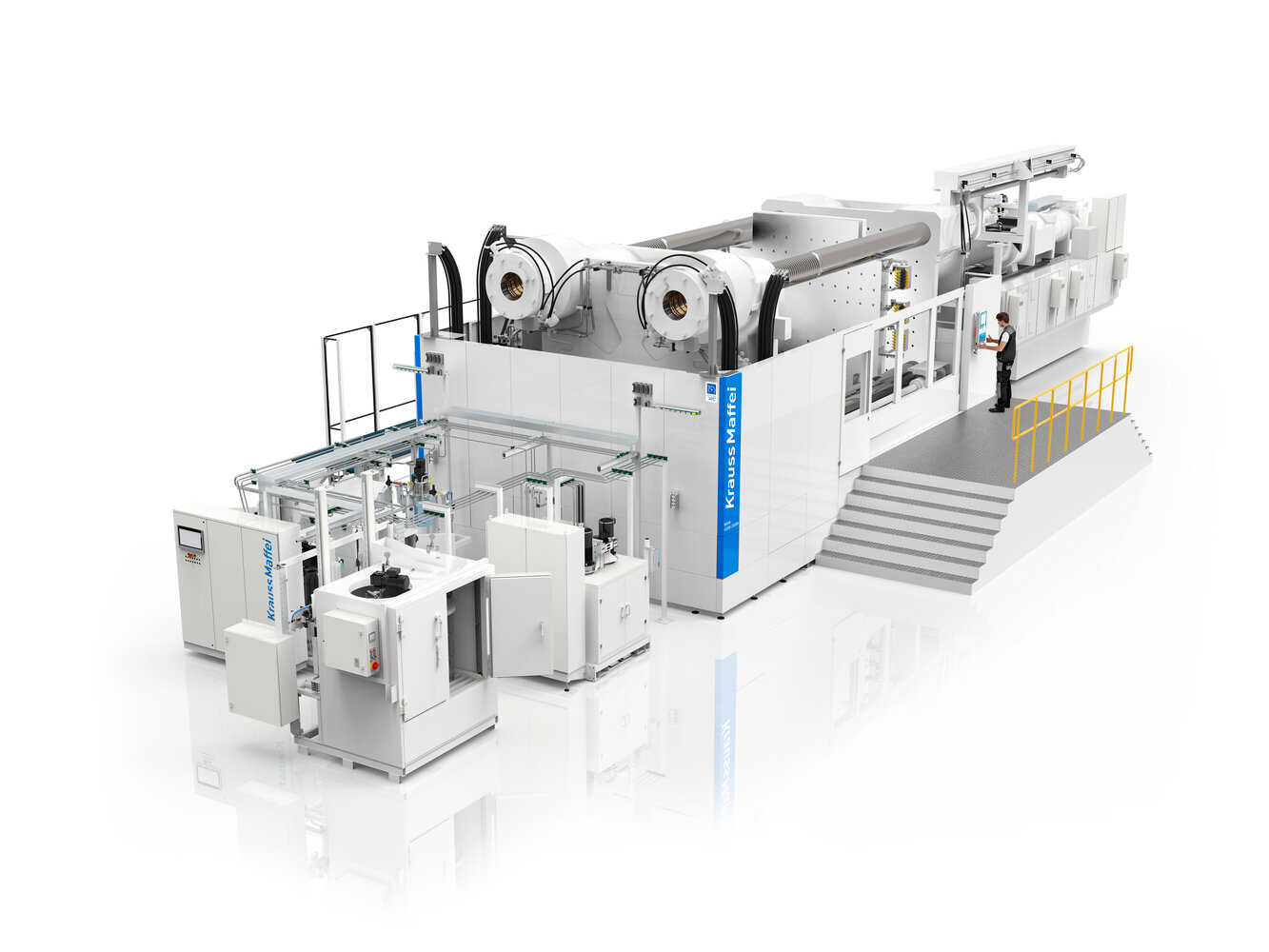

The system consists of a combined IMM and RPM cell. An automation and post-processing system is also required for these high-quality surface parts.