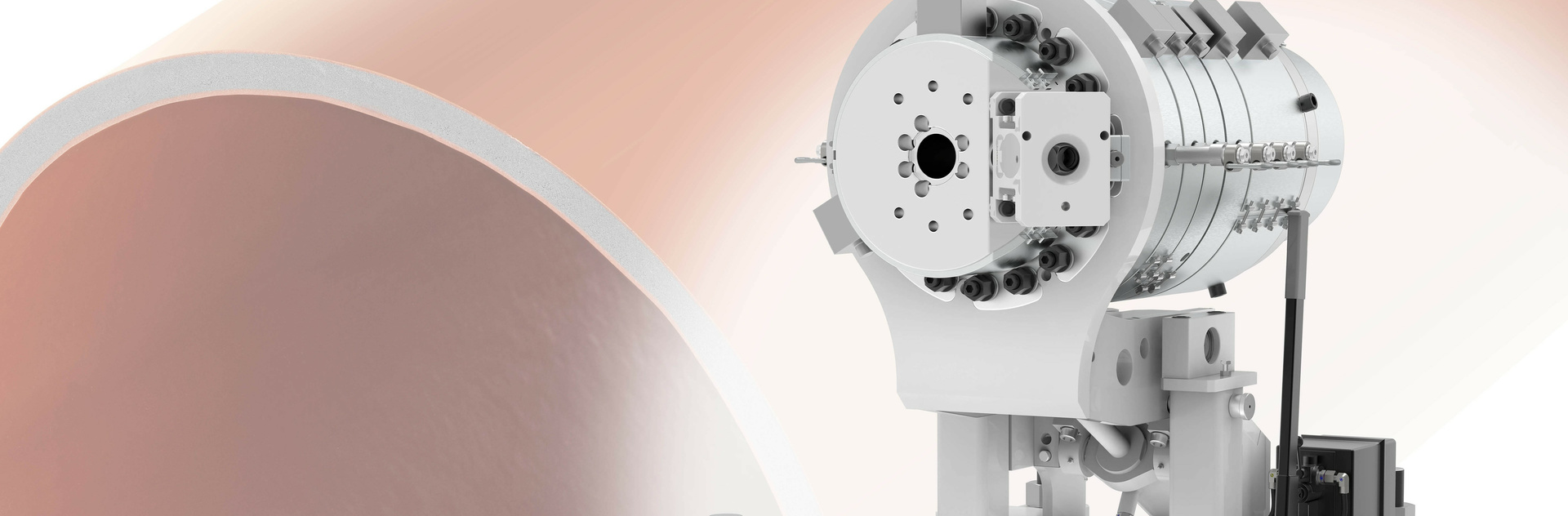

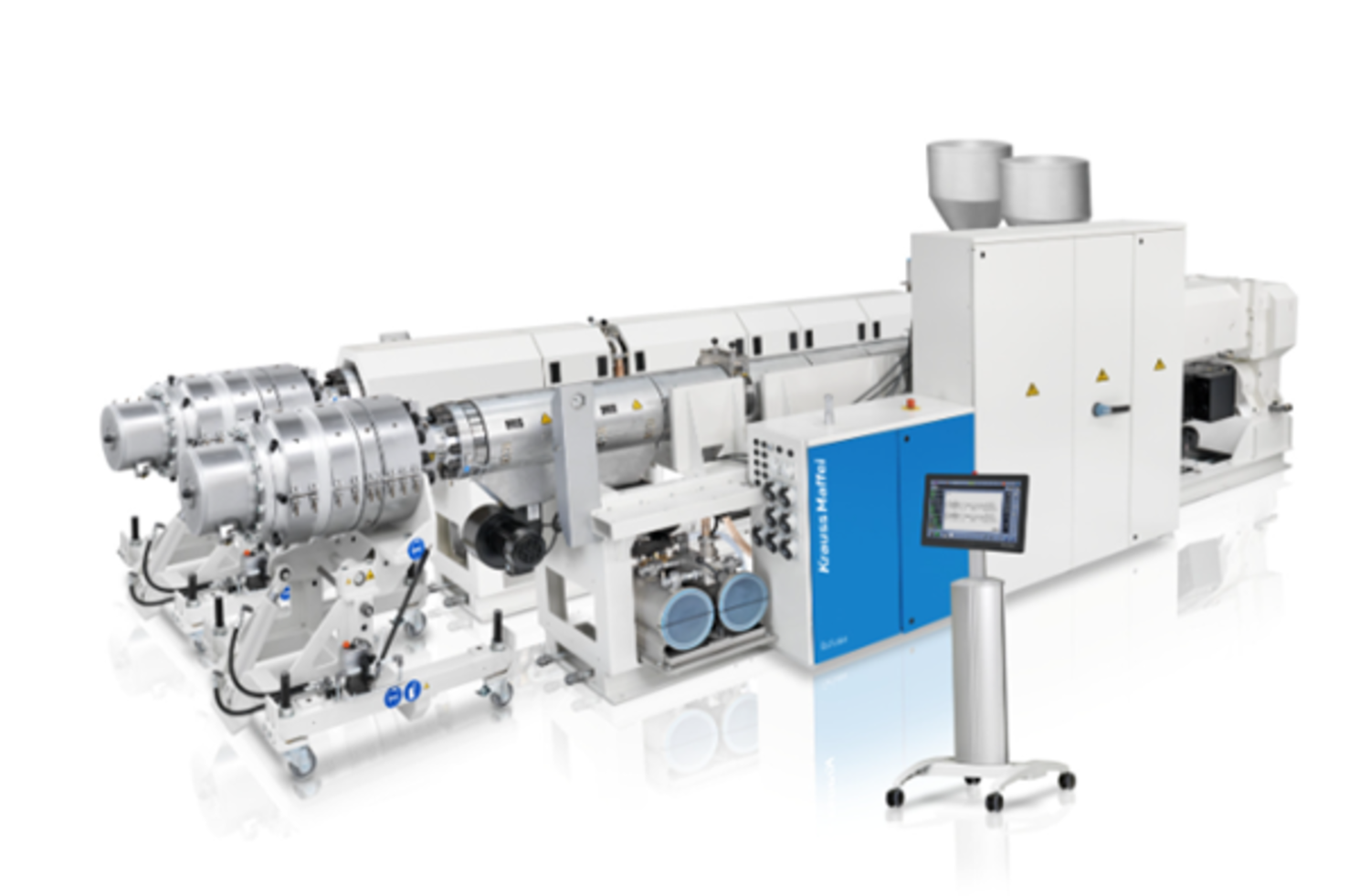

Counter-rotating Twin Screw Extruder (KMD)

Product information

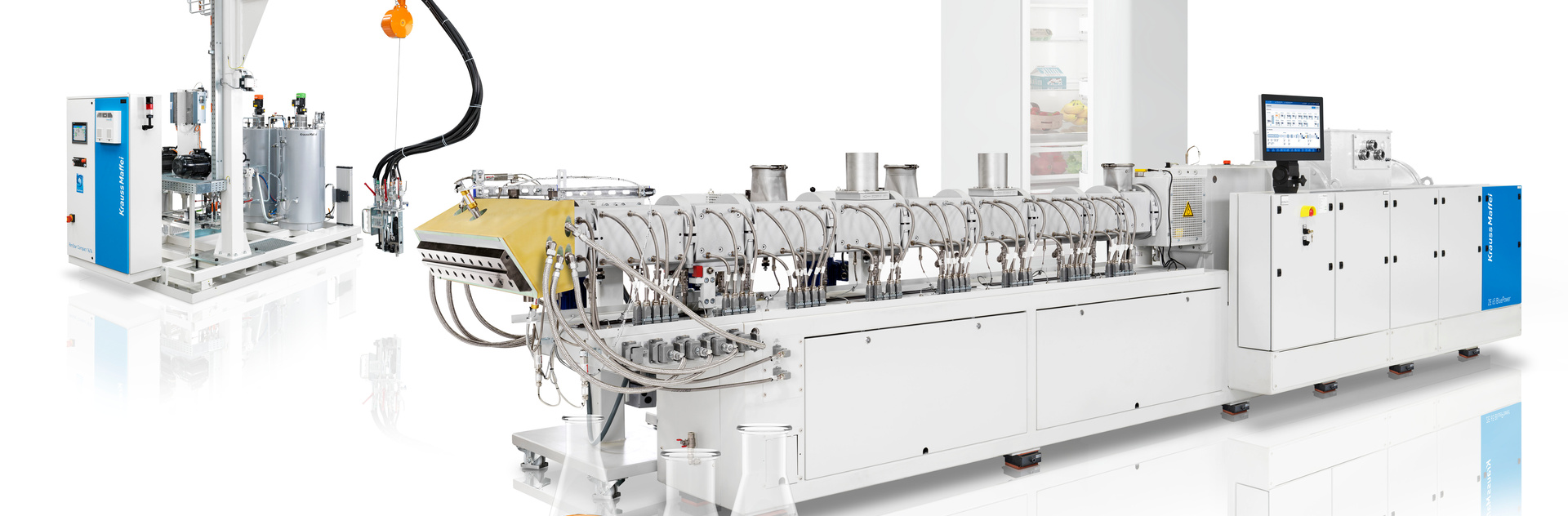

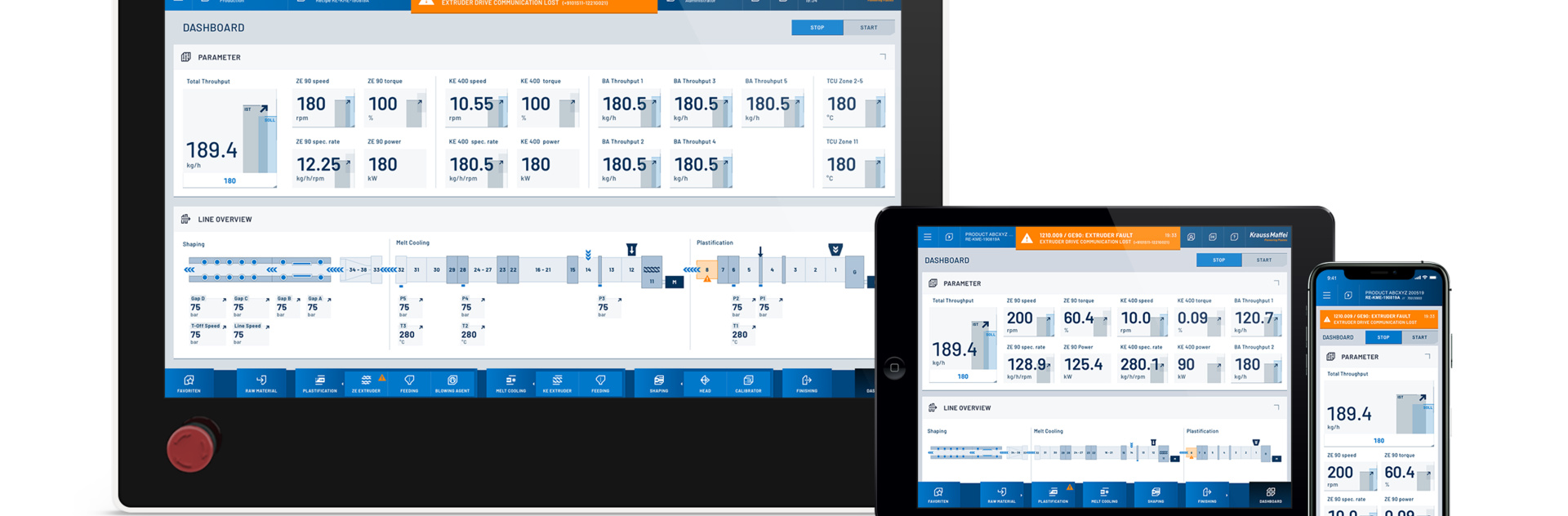

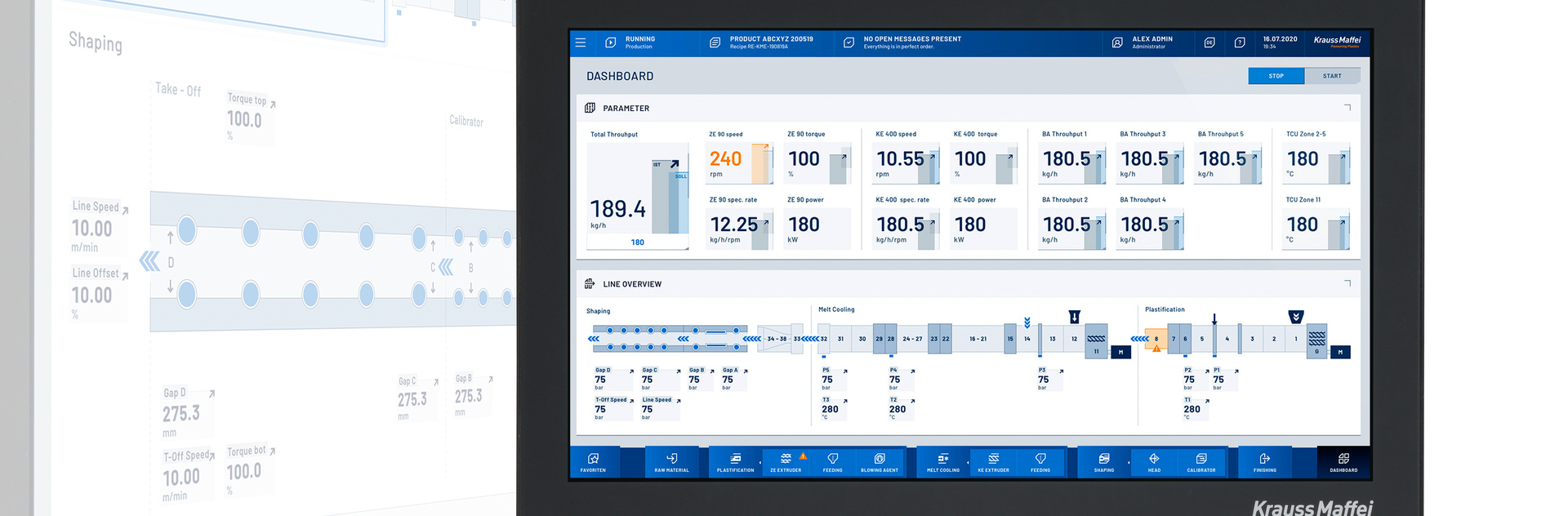

Our robust twin-screw extruders in the 36D, 32D, and 26D series guarantee you not only maximum output and first-class product quality, but also process-reliable and energy-efficient production. Whether for pipes, profiles, granules, sheets, or films, compact or foamed: Our systems combine technical precision with customer-friendly operation and offer maximum flexibility for individual requirements. Our counter-rotating twin-screw extruders are specially designed for PVC processing.

Performance data

Process lenghts: 36D, 32D, 26D

Up to 3200 kg/h Output capacity

Series: Conical, parallel, laboratory extruder

Why our product stands out

- Optimized screw design for U-PVC, M-PVC, PVC foam core, and PVC-O pipes

- Patented molybdenum welding layer on parallel twin screws for extended service life

- Modular extruder concept with high process flexibility for various formulations and materials

- Low maintenance effort thanks to internally tempered screws and air-cooled barrel

- High output rates, reliable degassing, and consistent production of single- and multi-layer pipes with excellent quality

Use cases

Industries

Infrastructure & Construction

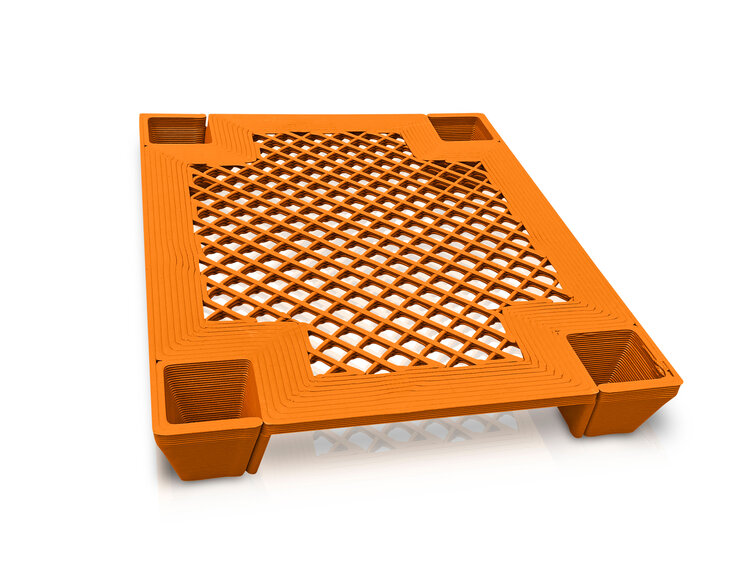

Packaging & Logistics

Cooling Technology & Insulation

Automotive

Electrical & Electronics

Circular Economy & Recycling

Klaus-Dieter Lorius

Teamlead Expert Sales Pipe & Profile