Linear mixing heads

Up to 10.000 gr/sec

Product information

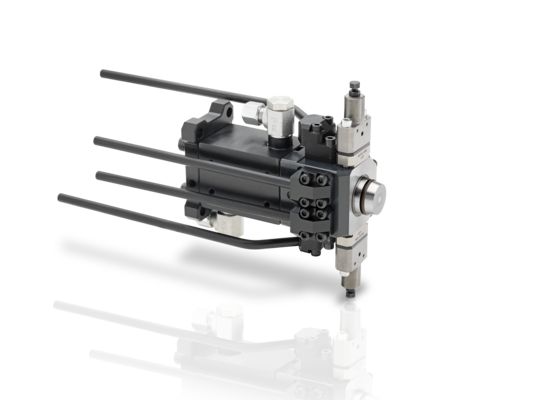

Both systems in our linear mixing head series stand for maximum reliability, a maintenance-friendly, self-cleaning design, and excellent mixing quality in high-pressure mixing. The controlled, laminar discharge makes them the ideal solution for demanding PUR applications—tailored to your processes.

- Self-cleaning, maintenance-friendly design

- Exceptional reliability and durability

- Tailor-made for your application

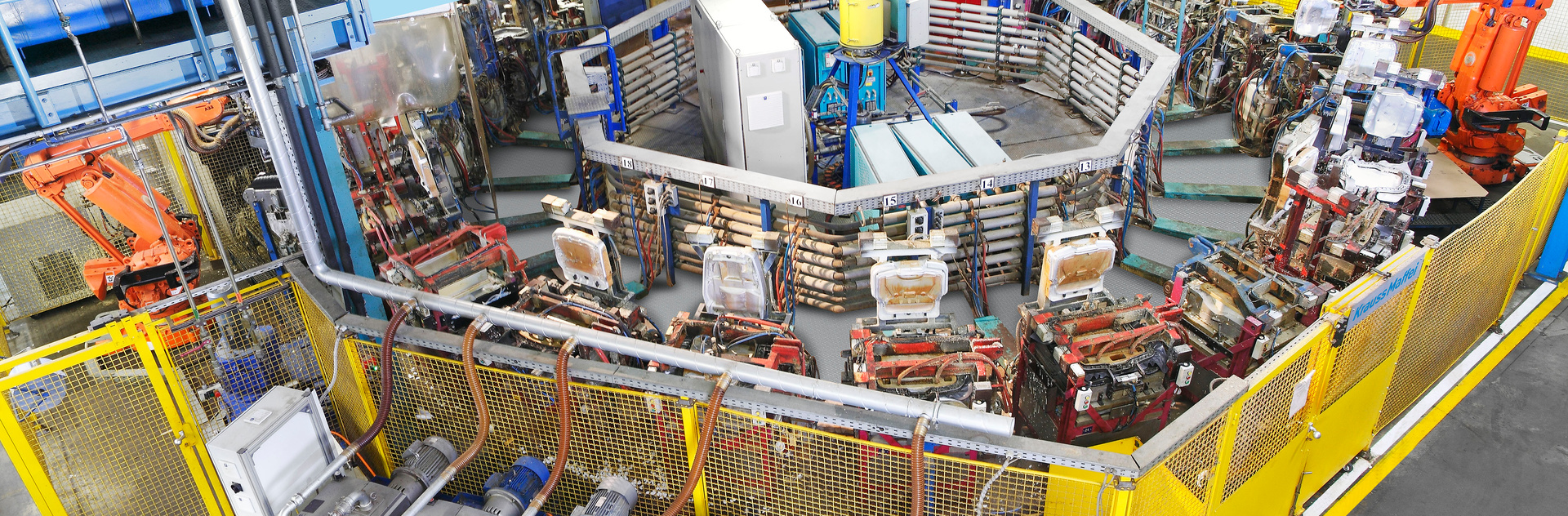

Use cases

Industries

Proven, reliable, and the cost-effective alternative for total laminar discharge

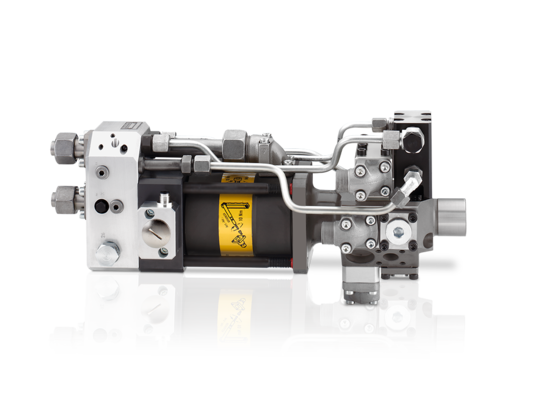

The linear mixing heads utilise the countercurrent injection principle, which enables particularly intensive mixing of the components by converting pressure into mixing energy. They are available in several versions and offer a high degree of flexibility for different production requirements. Linear mixing heads are ideal for a wide variety of filled and unfilled components in the automotive industry.

Core features of linear mixing heads

- Self-cleaning mixing head

- Cartridge technology simplifies the replacement of nozzle elements

- Minimum shot time of 0.3 s possible (depending on the polyurethane system)

- Electronic shot time recording for minimum shot weight tolerances

- 2–5 components

- Control piston with recirculation grooves

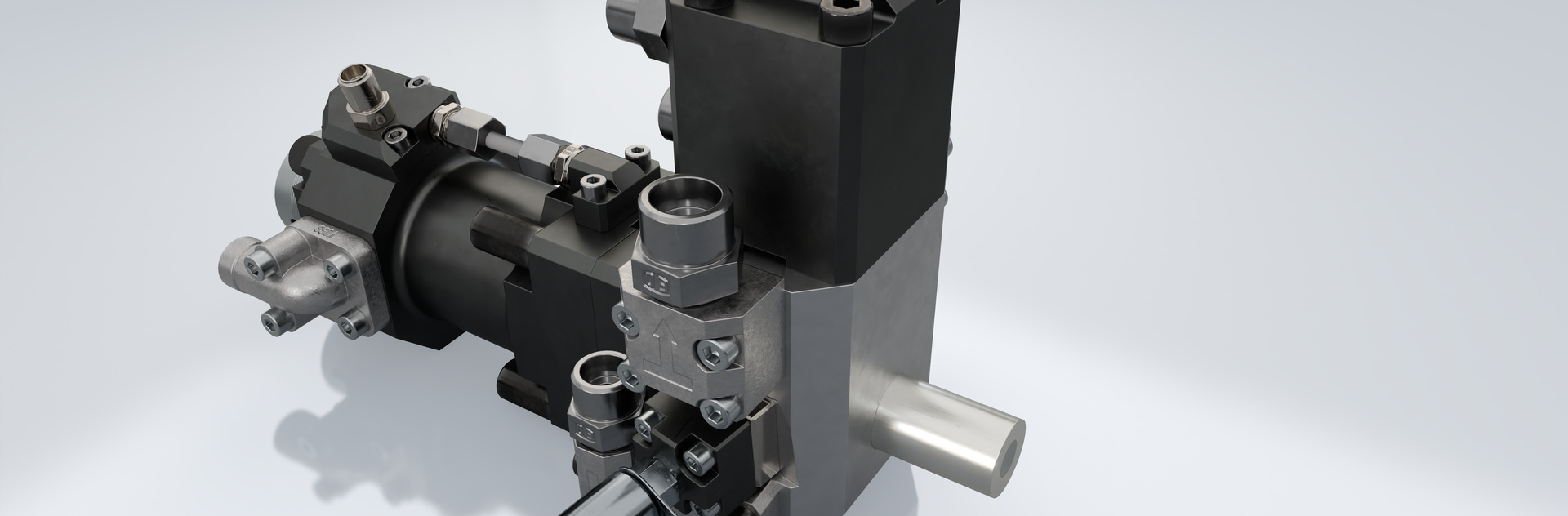

The MKE-3B mixing head is based on the proven T-mixing principle, which ensures a laminar PUR flow and optimum homogenization. Two mixing fronts efficiently convert the injection energy, while stabilizing pins stabilize the flow and further improve the mixture.

Core features of the MKE-3B mixing head

- Mixing of raw material components according to the T-mixing principle

- Very fast shot sequence: opening and closing in less than 0.5 seconds

- Simple and safe hydraulic forced control