Welcome to KraussMaffei

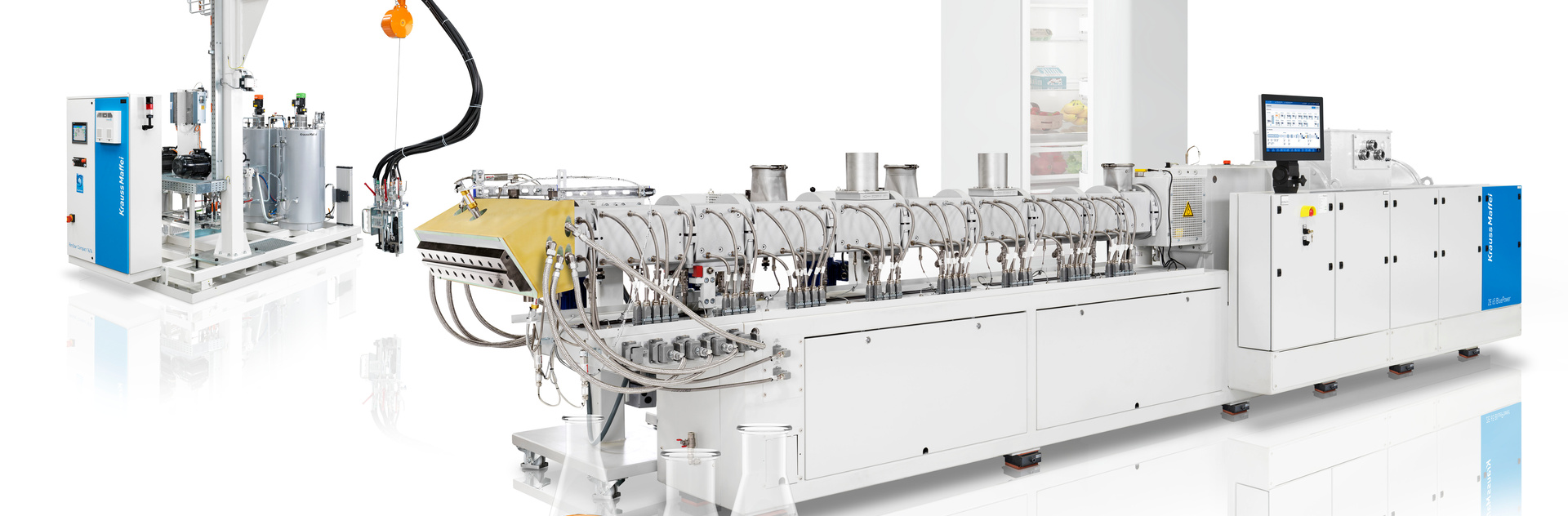

Pioneering Plastics: Together, we are breaking new ground. KraussMaffei combines four technologies, the matching automation, digital products and excellent service under one roof. Our around 4000 employees worldwide are constantly developing the right solutions for a range of industries. Together with our customers, we are rethinking plastics and shaping the industry of the future.

KraussMaffei in Figures

1838

Foundation year

4200

Colleagues

17

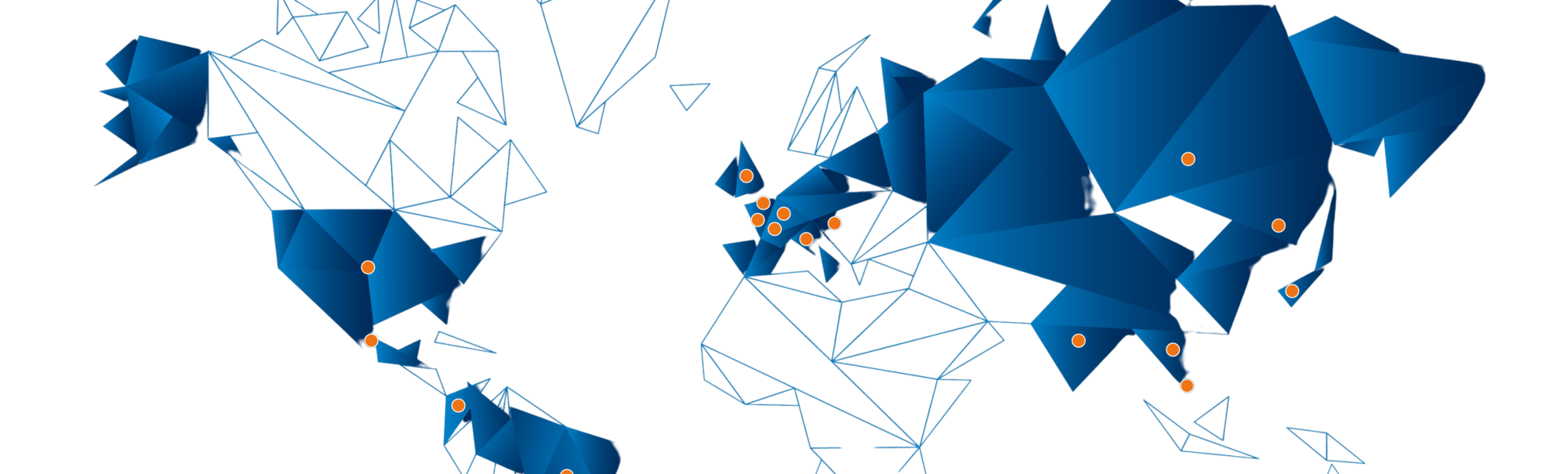

Countries

4

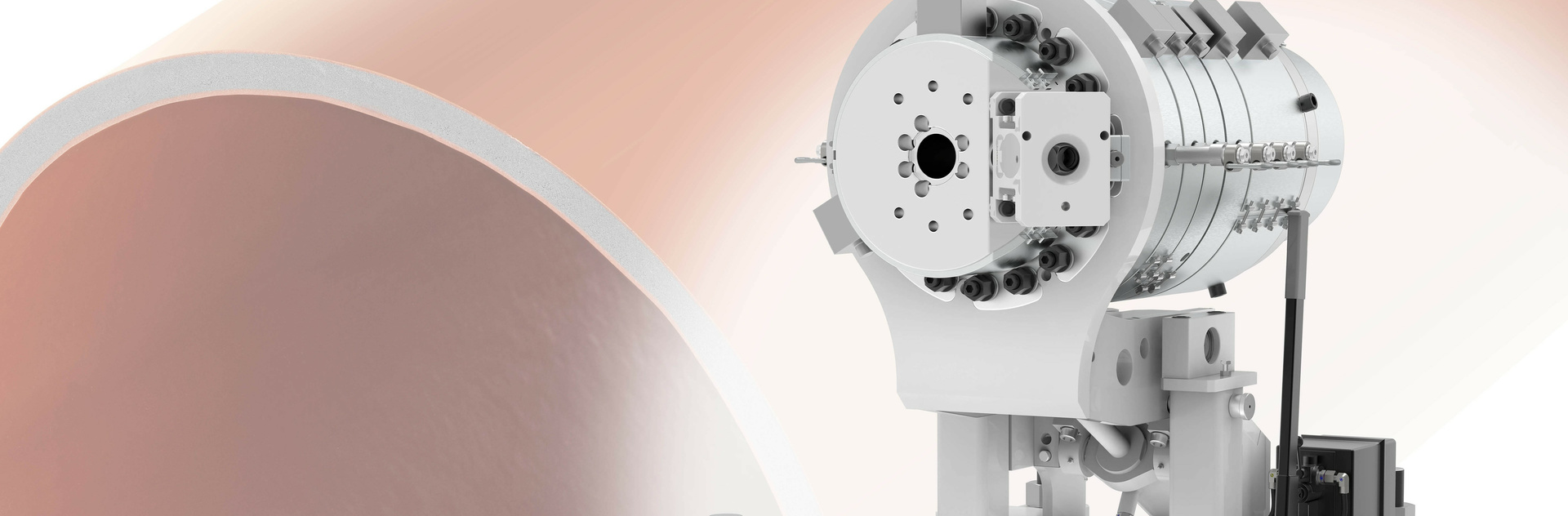

Technologies

11

Number of industries

586

Patents

9

Training professions

31

Locations worldwide

6

Social media channels

News from KraussMaffei

Visit our AHEAD Blog

December 10, 2025

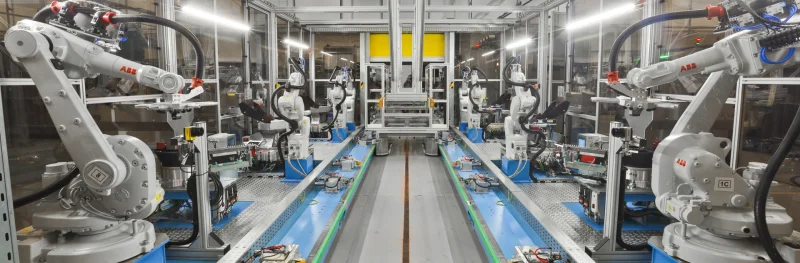

Perfection in 40 seconds

How KraussMaffei Viersen automates the assembly of door interior trim for premium vehicles

December 3, 2025

“We are growing with PVC-free medical compounds”

Success story Melitek

November 18, 2025

For the “Crème de la Crème”

Novassu produces closures for premium cosmetics