About KraussMaffei

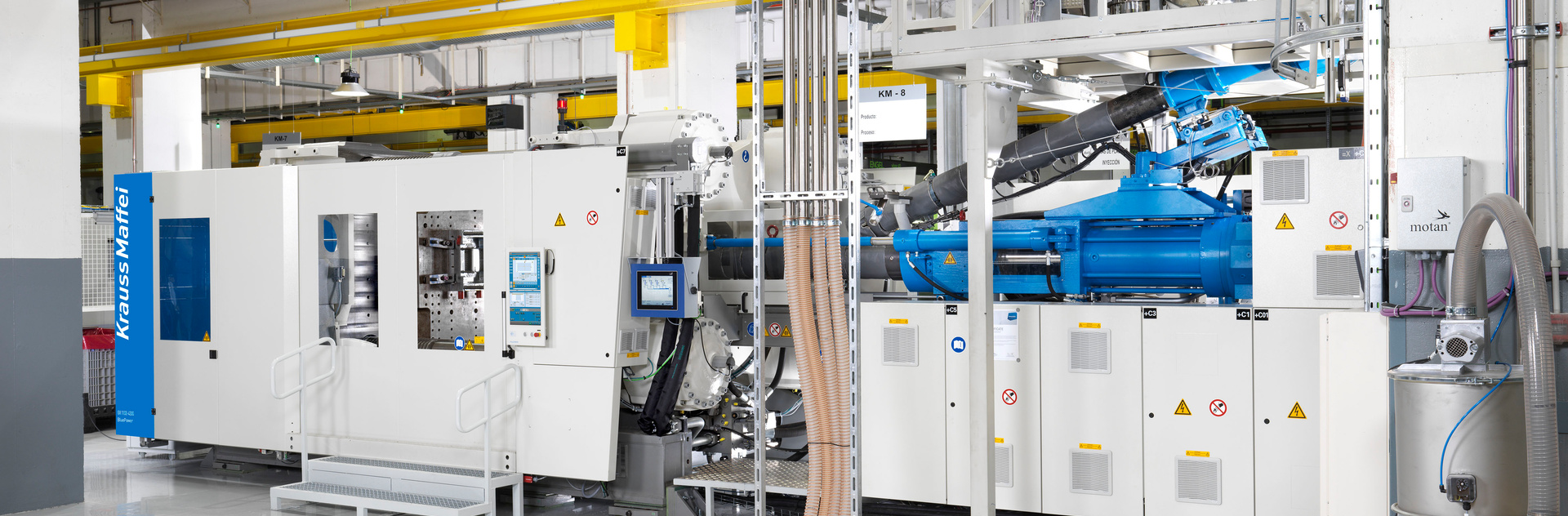

Our company offers all technologies in the fields of injection molding, extrusion and reaction process machinery, as well as automation and Additive Manufacturing - a unique selling point in the industry. With this broad range of services, we develop innovative solutions for the automotive, packaging, medical and construction industries, as well as for the manufacturing of electrical and electronic products and household appliances.

KraussMaffei employs around 4,000 people worldwide. With over 30 subsidiaries, more than 10 manufacturing plants, and roughly 570 trade and service partners, we are well positioned to quickly service our customers' needs.

KraussMaffei Stories

From our AHEAD blog

April 9, 2025

Revolutionizing air mobility

FiberForm speeds up eVTOL production in record time

September 2, 2024

Live @Fakuma: The Turtle project

All-electric PX presents high-quality sandwich application with recyclate

June 5, 2024

The better wood

Teaching materials specialist Wissner manufactures its products from Re-Wood® on KraussMaffei machines

April 24, 2024

From passenger to cargo aircraft

Renowned NIAR Institute relies on FiberForm technology from KraussMaffei

April 9, 2024

Live @NPE: Future mobility

Clemson University showcases driverless concept vehicle

March 19, 2024

Circular Economy live @NPE

Complete material cycle from medical blood vials to bottle openers

March 11, 2024

Button in the ear

The new precisionMolding produces TPU ear tags for livestock

December 8, 2023

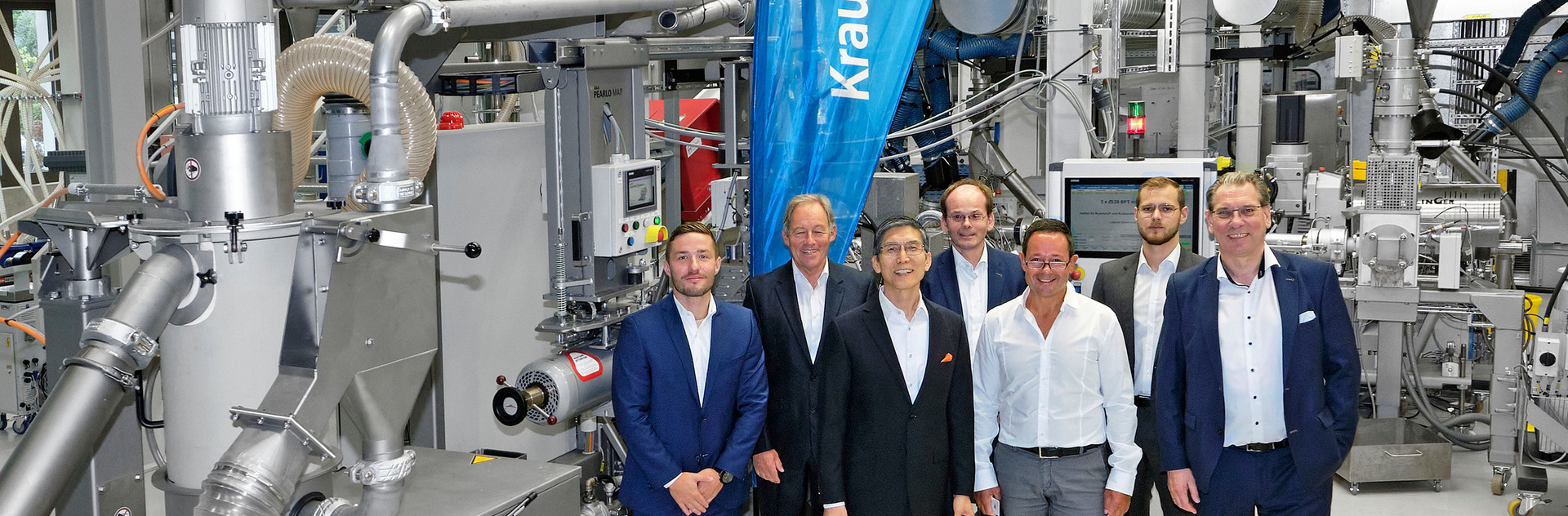

A successful Partnership

KraussMaffei Extrusion and the IKK - Institute of Plastics and Circular Economy at Leibniz University Hannover (LUH)

November 30, 2023

In-house recycling at KraussMaffei

Transport crates made of plastic waste

October 11, 2023

Reducing CO2 emissions twice over

Thermoplastic foam injection molding with post-consumer recyclate

September 18, 2023

MuCell in sight

Live @Fakuma: Foamed component with IML decoration and new screw

May 22, 2023

Additive processing of recompounds

Sustainable and efficient component manufacturing

January 24, 2023

From the sea into the tunnel

Oldroyd uses 100% seaplastics for its products

November 23, 2022

For more sustainable coffee enjoyment

How Gebaplast uses coffee grounds to produce new stylish cup coasters

November 9, 2022

Keep the recipe in check

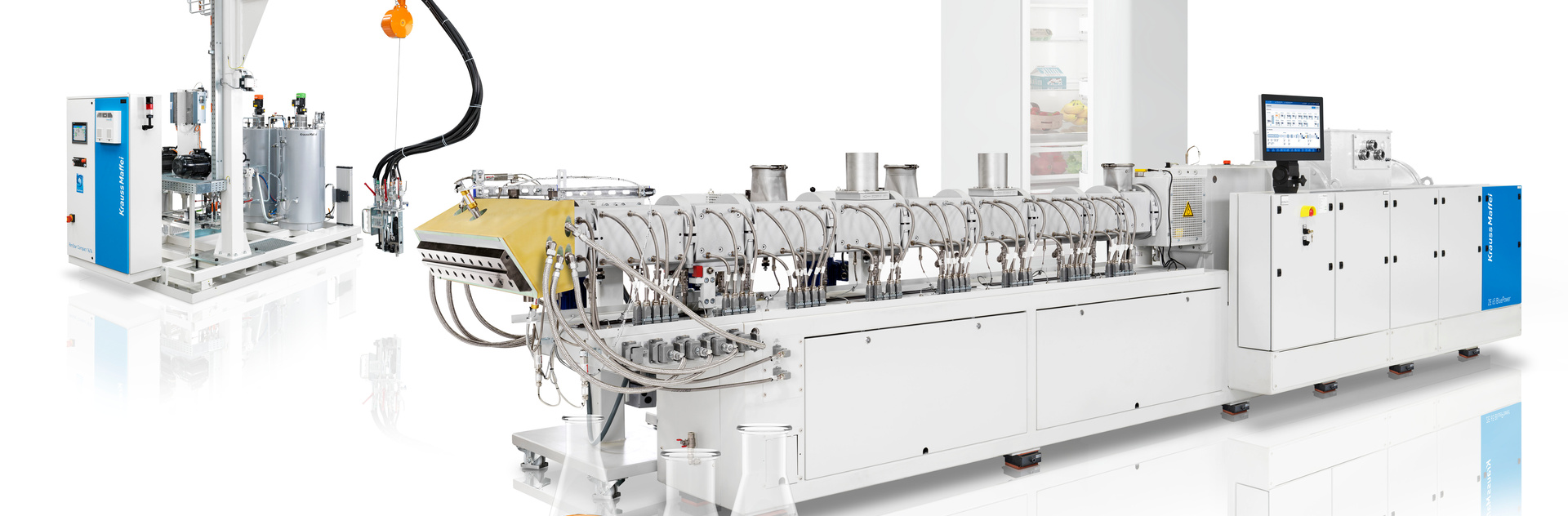

DCIM direct compounding: ZF Vigo gains control over the material with KraussMaffei

September 28, 2022

Digital solutions for Circular Economy

KraussMaffei leverages competencies of its three business units

September 8, 2022

Sustainable and efficient toy production

New precisionMolding at K with bio-plastics application

July 19, 2022

New material made from three recyclates

Live at K 2022: Reusable crates made with three recyclates