La responsabilité chez KraussMaffei

Tout le monde parle de durabilité. Nous préférons agir plutôt que discuter. En effet, c’est notre responsabilité en tant qu’entreprise. Cependant, pour nous, cela représente bien plus qu’une simple responsabilité : c’est une opportunité exceptionnelle.

- Nous développons et mettons en place de nouvelles machines et de nouveaux systèmes afin d’aider nos clients à respecter les exigences légales et à améliorer la durabilité de leur chaîne d’approvisionnement et de leurs opérations.

- Cela nous permet de repenser et d’optimiser les méthodes de production, offrant ainsi à tous les collaborateurs un lieu de travail plus agréable.

- C’est aussi une chance de préserver notre planète, pour nous et les générations futures.

Télécharger le rapport ESG 2023

Technological Excellence

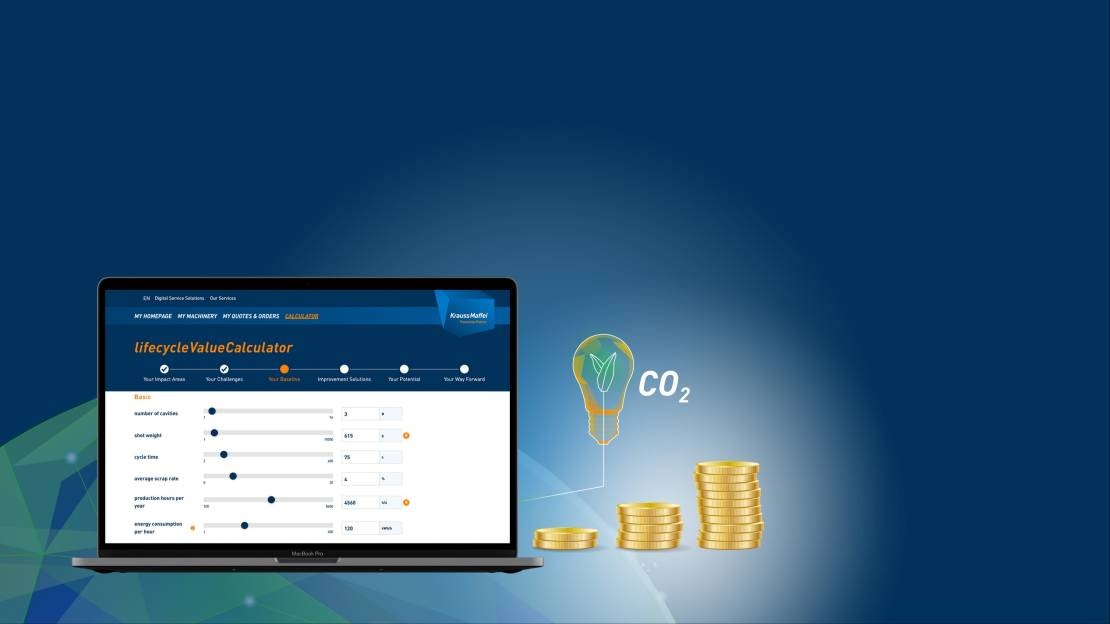

We have the greatest leverage for greater sustainability through our machines and systems. Here are some current examples of how we use them to help our customers achieve their own sustainability goals.

Sustainability starts with our own behavior

-

Seal of approval from the German Sustainable Building Council (DGNB) for the Laatzen and Parsdorf sites

-

Commissioning of one of Europe's largest rooftop PV systems with an output of 9.1 MWp at the Parsdorf site By 2023, we will have generated 46% of our electricity requirements ourselves at the new Parsdorf site

-

Optimization of the compressed air system at the Sučany (SK) site

-

Definition of the requirements “energy efficiency” and “emission reduction” as elementary components of all development processes for machines and systems

-

Introduction of the environmental management system in accordance with DIN 14001 at the Laatzen site and recertification of the environmental management system in accordance with DIN 14001 at the Parsdorf site

-

Savings of approx. 4,428 kWh p.a. by switching to LED lighting at the Abbiategrasso site (Italy)

-

Recycling rate of waste and leftover production materials amounted to 85% at the Allach and Parsdorf sites in 2023 (this rate also includes all waste and other production materials generated as part of the move from Allach to Parsdorf this year)